In summer heat, circuits in EV chargers derate because high temperatures cause components to operate outside their safe limits, increasing resistance and risking failures. Heat causes materials to expand, weaken insulation, and reduce safety margins, which can lead to overheating or damage. To prevent issues, manufacturers lower current capacities and implement cooling strategies. Continuing this exploration will reveal how material choices and maintenance help keep your charging station safe and efficient in hot weather.

Key Takeaways

- Increased heat raises conductor resistance, reducing current-carrying capacity and necessitating derating for safety.

- High temperatures accelerate insulation degradation, risking electrical faults and requiring circuit adjustments.

- Thermal expansion can misalign components, weakening connections and prompting derating to prevent failures.

- Elevated summer temperatures impair component performance, prompting safety margins to be reduced via derating.

- Effective thermal management, such as cooling and ventilation, helps mitigate heat effects and maintain circuit reliability.

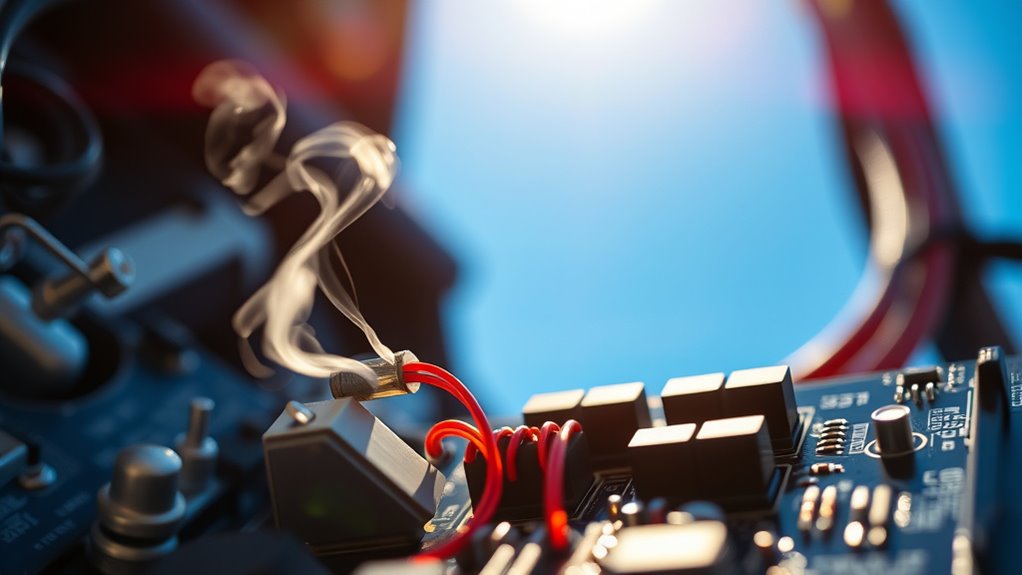

How Heat Affects Electrical Components in EV Chargers

Heat can substantially impact the performance of electrical components in EV chargers. As temperatures rise, thermal expansion occurs in metals and other materials, causing components to slightly enlarge. This expansion can lead to misalignments or loose connections, increasing resistance and risking failure. Additionally, excessive heat accelerates insulation degradation, weakening the protective barriers that prevent short circuits. When insulation deteriorates, the risk of electrical faults increases, potentially damaging the charger and reducing efficiency. High temperatures also cause components like capacitors and resistors to operate outside their ideal ranges, impairing functionality. Understanding these effects highlights the importance of managing heat in EV chargers, ensuring they operate safely and reliably even during hot summer conditions.

The Science Behind Circuit Derating During High Temperatures

When temperatures rise, the resistance in conductors increases, making circuits less efficient and more prone to overheating. Material ratings also drop as components heat up, reducing their safe operating limits. To protect your system, safety margins are reduced, ensuring risks are minimized even under high-heat conditions. Additionally, elevated temperatures can impair the performance of electrical components, further emphasizing the importance of derating in hot environments. Recognizing circuit safety guidelines is essential for maintaining reliable operation during extreme temperatures. Moreover, understanding thermal management techniques can help mitigate heat-related issues and extend the lifespan of electrical systems. Incorporating AI-driven monitoring can provide real-time insights into thermal performance, helping to prevent failures before they occur. Implementing proper cooling solutions is also critical to maintaining circuit integrity in high-temperature scenarios.

Resistance Increase in Conductors

Have you ever wondered how high temperatures affect electrical conductors? When temperatures rise, conductor resistance increases because of heat expansion. As a conductor heats up, its atoms vibrate more, making it harder for electrons to flow smoothly. This resistance rise can cause a drop in current-carrying capacity, leading to circuit derating. The heat expansion slightly enlarges the conductor’s size, but this doesn’t offset the resistance increase; instead, it often worsens the problem. Additionally, conductor materials can influence how much resistance increases with temperature. Consequently, the conductor needs to handle less current to avoid overheating and potential failure. Understanding how resistance increases with heat helps explain why electrical systems must be carefully rated for high-temperature environments, especially during summer or in hot climates.

Material Temperatures Affect Ratings

As the temperature of circuit materials rises, their electrical ratings decline because the properties of the materials themselves change. Increased heat causes thermal expansion, which can loosen connections and create stress points. Over time, repeated thermal cycling leads to material fatigue, weakening components and increasing failure risk. Higher temperatures also accelerate degradation of insulation, reducing dielectric strength. You might notice:

- Material expansion causing misalignment

- Accelerated fatigue weakening conductors

- Insulation deterioration lowering safety margins

- Increased risk of microcracks forming in solid materials

These effects combine to lower circuit performance and reliability, making it essential to understand how temperature impacts material properties and ratings. Managing heat is vital to prevent damage caused by thermal expansion and material fatigue, ensuring longevity and safety of your electrical systems. Additionally, thermal management strategies are crucial in maintaining circuit integrity during high-temperature conditions. Proper ventilation and cooling techniques can help mitigate these temperature-related issues and extend the lifespan of electrical components. Implementing temperature control measures is also important for maintaining consistent circuit performance under varying environmental conditions. Understanding the material responses to heat can help in selecting suitable components for high-temperature environments and avoid premature failures. Recognizing how heat accelerates material degradation underscores the need for effective thermal design in electrical systems.

Safety Margins Reduce Risk

High temperatures cause circuit components to operate closer to their maximum limits, reducing their safety margins. As thermal expansion occurs, conductors expand, which can compromise connections and increase resistance. This makes circuits more vulnerable to overheating or failure. By derating components, you intentionally lower current levels, maintaining a buffer against extreme conditions. Reduced safety margins help prevent damage caused by decreased conductor flexibility, which becomes stiffer at high temperatures, risking cracks or breaks. These adjustments give your system a built-in safeguard, minimizing the chance of overheating, electrical fires, or component failure. Virtually, derating acts as a protective measure, ensuring your circuits stay within safe operating limits despite the stresses of high heat. Additionally, understanding thermal properties helps in designing circuits that can better withstand temperature fluctuations, and considering material expansion is crucial for reliable system performance. Recognizing the importance of AI security in monitoring and adapting to changing conditions can further enhance circuit resilience in demanding environments.

Common Signs of Heat-Related Derating in EV Charging Stations

Heat can cause EV charging stations to reduce their performance, often signaling underlying issues. You might notice signs like increased charging times or inconsistent power delivery, indicating thermal expansion affecting internal components. Over time, the station’s electronics may overheat, triggering automatic derating to prevent damage. Watch for visible signs such as melting or warping of heat shielding, which helps manage temperature. You might also see warning lights or error messages related to thermal overload. Additionally, frequent shutdowns or reduced output during hot days suggest the system is protecting itself from excessive heat. These indicators point to heat-related derating, emphasizing the importance of proper heat management. Proper cooling systems play a crucial role in preventing such issues and maintaining optimal performance. Ensuring proper ventilation can also help dissipate heat more effectively. Implementing effective thermal management solutions can further mitigate risks associated with high temperatures. For example, temperature regulation techniques are vital in safeguarding sensitive electronic components. Recognizing heat dissipation as a key factor in system design can help extend the lifespan of charging stations. Identifying these signs early can prevent hardware failure and ensure reliable charging performance.

Materials and Design Factors Influencing Heat Tolerance

Your choice of materials directly affects how well a circuit can handle heat, with high conductivity helping to spread heat more evenly. Good design also prioritizes efficient heat dissipation to prevent hotspots and reduce thermal stress. By understanding these factors, you can improve circuit durability and performance in high-temperature environments. Additionally, selecting durable materials that withstand prolonged heat exposure can further enhance the longevity and safety of electrical systems. Incorporating thermal management techniques, such as heat sinks or cooling fans, can further optimize heat distribution and prevent circuit derating during hot summer conditions. Proper material selection can also help mitigate the risks associated with thermal runaway, ensuring safer operation under high heat conditions.

Material Conductivity Impact

Material conductivity plays an essential role in how well a circuit can withstand heat, as it determines how efficiently heat is transferred away from critical components. Variations in material properties mean some substances conduct heat better than others, affecting overall heat management. Higher conductivity materials, like copper or aluminum, quickly disperse heat, reducing overheating risks. Conversely, materials with low conductivity, such as plastics or ceramics, trap heat, making circuits more prone to derating. Understanding conductivity variations helps you select appropriate materials to improve heat tolerance. For instance, selecting materials with high thermal conductivity can significantly enhance heat dissipation and circuit reliability. Copper’s excellent conductivity aids in heat dissipation. Aluminum offers a balance of conductivity and weight. Plastics insulate, trapping heat in components. Ceramic materials resist high temperatures but are brittle. Additionally, integrating thermal management techniques, such as heat sinks and cooling systems, can further mitigate heat-related derating issues.

Design for Heat Dissipation

Effective heat dissipation in circuit design relies on selecting appropriate materials and incorporating thoughtful design features that promote efficient airflow and thermal management. Using materials with good thermal conductivity helps transfer heat away from critical components. Incorporating heat shielding protects sensitive parts from excessive heat, especially during thermal expansion cycles. Proper layout design also minimizes hot spots and enhances airflow. Consider these factors when designing circuits:

| Material Type | Functionality | Key Feature |

|---|---|---|

| Aluminum | Heat sinking, thermal management | High thermal conductivity |

| Ceramic | Insulation, heat shielding | Thermal stability |

| Copper | Conducts heat, electrical wiring | Excellent heat transfer |

Additionally, selecting materials with thermal stability ensures consistent performance under temperature fluctuations.

Strategies for Managing Heat to Maintain Charging Performance

Managing heat is essential to maintaining ideal charging performance in circuits. Effective thermal management helps prevent overheating that can cause derating or failure. You can implement ventilation techniques such as adding fans or vents to improve airflow, which helps dissipate heat quickly. Using heat sinks or thermal pads can absorb excess heat directly from critical components. Regularly inspecting and cleaning cooling systems guarantees optimal performance. Additionally, consider insulating sensitive parts to protect against external heat sources. Incorporate temperature sensors that trigger cooling mechanisms when thresholds are reached. These strategies work together to keep circuits cool, ensuring consistent and reliable EV charging. Prioritizing thermal management not only extends your equipment’s lifespan but also maintains peak charging performance during summer heat.

Regulatory Standards and Safety Considerations for Hot Weather

When temperatures soar, regulatory standards and safety considerations become critical for guaranteeing reliable and secure EV charging in hot weather. These standards address thermal expansion, which can cause components to shift or crack if not properly managed, risking short circuits or failures. Insulation requirements are also essential; they ensure that heat doesn’t compromise electrical safety or cause overheating. Regulations specify materials and installation practices designed to withstand high temperatures, preventing damage and minimizing fire risks. Adherence to these standards helps protect both users and infrastructure. By following localized codes and manufacturer guidelines, you guarantee your charging setup remains safe and effective, even during extreme heat. Staying compliant helps avoid penalties and reduces the risk of accidents caused by heat-related stress on electrical components.

Best Practices for Inspecting and Maintaining Charging Infrastructure in Summer

As summer heat rises, it’s essential to proactively inspect and maintain your EV charging infrastructure to prevent issues caused by high temperatures. Elevated ambient temperature can lead to thermal expansion in connectors, wiring, and equipment, risking damage or malfunction. Regular inspections help identify signs of wear, corrosion, or loose connections before problems escalate. Keep an eye on these best practices:

- Check for signs of thermal expansion, such as cracking or deformation.

- Tighten loose connections that may loosen with heat.

- Clean dust and debris to improve cooling and airflow.

- Verify that cooling systems, vents, and fans operate correctly.

Performing these steps ensures your infrastructure remains safe, reliable, and efficient during hot summer months, preventing derating and electrical failures caused by heat-related stress.

Frequently Asked Questions

How Does Ambient Temperature Impact EV Charging Speed?

Higher ambient temperatures can slow your EV charging speed because heat causes thermal expansion in electrical components, increasing resistance. Elevated temperatures may also affect the circuit’s thermal management, leading to derating to prevent damage. Additionally, high ambient humidity combined with heat can create condensation, which further impacts electrical performance. As a result, your charging process becomes less efficient, and you might experience longer charging times during hot summer days.

Are There Specific Materials That Better Resist Heat in Chargers?

You’ll find that chargers made with heat resistant materials, like certain ceramics or high-grade plastics, better resist heat and improve durability. Thermal insulation also plays a key role by reducing heat transfer, keeping the internal components cooler. These materials help prevent overheating during summer, maintaining charging speed and safety. When choosing a charger, look for those that incorporate thermal insulation and heat resistant materials to guarantee reliable performance in hot weather.

Can Heat Derate Affect Charging Station Lifespan?

Ever wondered if heat derate impacts your charging station’s lifespan? It definitely can, as thermal expansion causes materials to expand and contract repeatedly, leading to material fatigue over time. This stress accelerates wear on components, reducing their durability and potentially causing failures. So, yes, sustained high temperatures can shorten your charger’s longevity by promoting these effects, emphasizing the importance of proper cooling and heat management for long-term reliability.

What Are the Long-Term Effects of Repeated Heat Exposure?

Repeated heat exposure causes thermal fatigue and accelerates material degradation in your charging station components. Over time, this can lead to cracks, weakened connections, and reduced reliability. As the materials break down, you might notice increased malfunctions or safety issues. To prevent long-term damage, guarantee proper ventilation, use heat-resistant materials, and regularly inspect your charging station, especially during hot summer months, to maintain safe and efficient operation.

How Do Cooling Systems Prevent Circuit Derating in Summer?

Cooling systems prevent circuit derating in summer through effective thermal management and heat dissipation. They actively remove excess heat generated during high temperatures, maintaining ideal operating conditions. You can rely on fans, liquid cooling, or heat sinks to keep components cool. This prevents overheating, reduces the risk of damage, and guarantees your EV charging circuits stay efficient and safe, even during hot summer days.

Conclusion

As summer temperatures soar, understanding why your EV charger derates is vital to avoiding unexpected failures. Heat can turn your charging station into a ticking time bomb if not managed properly. By staying vigilant and following best practices, you can prevent minor heat issues from becoming catastrophic. Remember, ignoring heat effects is like playing with fire—trust me, you don’t want your charging infrastructure to turn into a molten mess at the worst possible moment.