LED drivers often fail early because of poor heat management, manufacturing defects, or internal component issues that cause overheating and accelerate wear. Signs like flickering, dimming, discoloration, or unusual noises indicate problems before complete failure. External factors such as inadequate ventilation or environmental stress can also shorten their lifespan. To keep your LED drivers working longer, make certain they’re properly cooled, rated for your environment, and sourced from reputable manufacturers. Keep exploring to learn more about protecting your LEDs.

Key Takeaways

- Thermal stress from poor heat dissipation causes internal overheating, leading to early LED driver failure.

- Manufacturing defects like poor soldering or substandard components increase the risk of early breakdown.

- Internal component vulnerabilities weaken durability and accelerate wear when exposed to heat or stress.

- External factors such as inadequate ventilation and environmental conditions contribute to overheating and failure.

- Regular inspection and choosing reputable brands with quality control can help detect issues early and prevent failures.

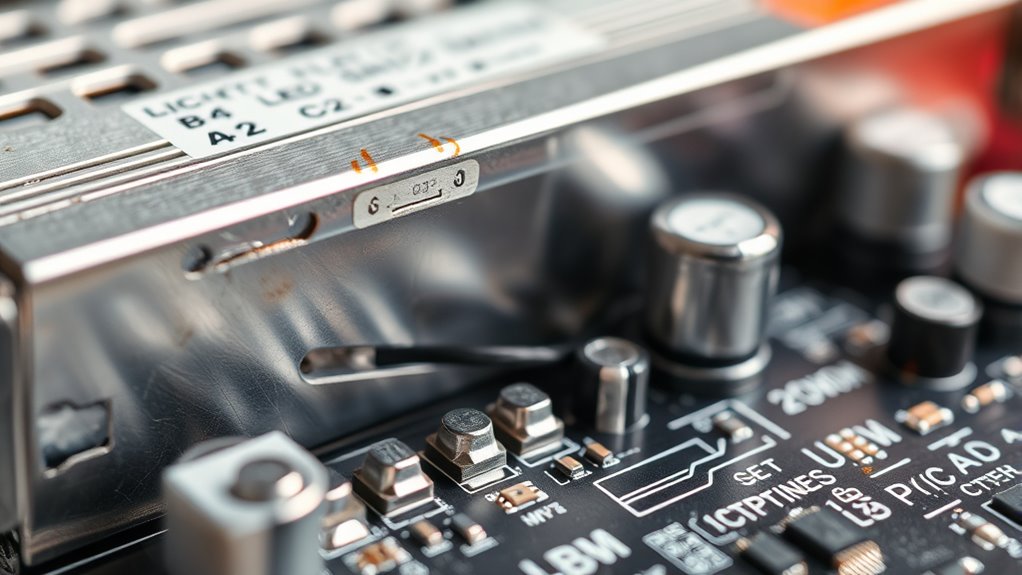

Many LED drivers are failing well before their expected lifespan, leaving you frustrated and your equipment underperforming. One of the main causes behind early failure is thermal stress. LED drivers generate heat during operation, and if that heat isn’t effectively managed, it can cause internal components to overheat. Over time, this heat accelerates wear and tear, leading to premature breakdowns. You might notice flickering, dimming, or complete failure sooner than anticipated. Proper heat dissipation, such as adequate cooling and ventilation, is essential to prevent thermal stress from damaging your drivers. If your setup lacks sufficient airflow or if the drivers aren’t rated for your specific environment, you’re increasing the risk of overheating and early failure.

Another significant factor is manufacturing defects. Sometimes, LED drivers leave the factory with hidden flaws—poor soldering, substandard components, or assembly errors—that compromise their durability. These defects might not be immediately apparent but can cause issues down the line, especially under normal operating conditions. Manufacturing defects often lead to inconsistent performance, unexpected shutdowns, or even complete failure within a relatively short period. When selecting drivers, it’s vital to buy from reputable manufacturers who adhere to quality control standards. Checking for certifications and reviews can help you identify reliable products less likely to be plagued by such defects.

You should also be aware that early failures aren’t always due to external factors; sometimes, the root cause lies in the manufacturing process itself. Low-quality components or shortcuts taken during assembly can make your LED driver more vulnerable to stress. For example, if the internal circuitry isn’t properly insulated or if components are mismatched, thermal stress can exacerbate these weaknesses, leading to rapid deterioration. Regular inspections and monitoring of your drivers can help you spot early signs of damage caused by manufacturing flaws. Look for signs like discoloration, burnt smells, or unusual noises, which often indicate internal component failure.

Understanding these causes puts you in a better position to prevent early failures. Ensure your drivers are rated for your operating environment, provide adequate cooling, and choose products from trusted manufacturers. By doing so, you minimize the risk of thermal stress and reduce the likelihood of encountering manufacturing defects. Taking these proactive steps helps extend the lifespan of your LED drivers, ensures consistent performance, and saves you money in the long run. Remember, early detection and proper maintenance are key to keeping your lighting systems running smoothly and efficiently.

Frequently Asked Questions

Can Environmental Factors Cause LED Driver Failure?

Yes, environmental factors can cause LED driver failure. Thermal stress from excessive heat damages internal components over time, while moisture ingress can lead to short circuits and corrosion. You should guarantee proper ventilation and use waterproof enclosures in humid or wet environments. Regularly inspecting your LED drivers for signs of overheating or moisture buildup helps prevent early failure and extends their lifespan.

How Often Should LED Drivers Be Inspected?

Think of your LED drivers as the heartbeat of your lighting system. You should inspect them every 6 to 12 months, depending on environmental conditions. Regular maintenance routines and testing procedures help catch early signs of failure before they turn into a flickering nightmare. Keep a close eye on temperature, moisture, and power surges, and perform these checks proactively to guarantee your lighting stays bright and reliable.

Are There Specific Brands More Prone to Early Failure?

Some brands are more prone to early failure due to inconsistent manufacturing quality and lower brand reputation. You should research brand reliability reviews and check for quality certifications before purchasing. Well-known brands with solid manufacturing standards tend to produce more durable LED drivers, reducing the risk of early failure. Avoid generic or unverified brands, as they often cut corners, increasing the likelihood of problems down the line.

What Are Signs of Imminent LED Driver Failure?

Imagine your LED driver as a delicate orchestra, vulnerable to discord. Signs of imminent failure include flickering, dimming, or unusual buzzing, like discordant notes. You might notice it feeling hot to the touch, signaling thermal stress, or see sudden light dimming after electrical surges. These symptoms warn you that the driver’s harmony is breaking down, and quick action can prevent a complete breakdown before it turns into a total blackout.

How Does Improper Installation Affect LED Driver Lifespan?

Improper installation can considerably shorten your LED driver’s lifespan. Wiring mistakes, like incorrect connections or loose wires, cause unnecessary stress and overheating. Voltage spikes from power surges can also damage the driver over time. To avoid this, make sure proper wiring and use surge protection. When installed correctly, your LED driver will operate efficiently and last longer, saving you money and preventing early failures.

Conclusion

To keep your LED drivers shining bright for years to come, stay vigilant about signs of wear and tear. Think of them as gentle whispers from your system, hinting that some parts might be tired. Regular checks and mindful attention can help you catch these subtle signals early, ensuring your lighting remains a steady, reassuring glow. With a little care, you’ll keep your environment illuminated and welcoming, avoiding the quiet fade that comes with neglect.