Clear, accurate panel labeling is essential for safe and efficient electrical work. Use organized labels that are durable, easy to read, and consistent, incorporating color codes, legends, and clear descriptions. Keep labels visible and update them whenever changes occur. Proper planning with suitable tools guarantees safety and quick circuit identification. If you want to learn how to create and maintain effective panel labels that make sense, continue exploring these essential tips.

Key Takeaways

- Use clear, standardized labels with descriptive terms for quick circuit recognition and error reduction.

- Incorporate visual cues like color coding and legends to enhance map clarity and usability.

- Ensure labels are durable, weather-resistant, and properly adhered to withstand environmental conditions.

- Regularly inspect and update labels to maintain accuracy and safety over time.

- Utilize digital or wireless mapping tools for detailed, easily updatable service panel layouts.

Understanding the Importance of Clear Circuit Labels

Clear circuit labels are essential for safety and efficient electrical work. Effective labeling helps you quickly identify circuits, reducing the risk of accidental shocks or outages. Using color coding makes labels even clearer, as different colors can represent specific areas or functions, streamlining troubleshooting. Equally important is label durability; labels must withstand heat, moisture, and handling over time to remain legible. Durable labels prevent fading or peeling, ensuring you always have accurate information at your fingertips. Properly labeled panels minimize errors during maintenance or emergency repairs, saving time and preventing costly mistakes. Investing in clear, well-constructed labels enhances overall safety and keeps your electrical system running smoothly. Proper labeling can also facilitate compliance with electrical safety standards and regulations. Clear circuit labels truly make a difference in managing your electrical panels effectively, especially when considering the importance of label durability in maintaining long-term readability. Additionally, choosing labels made from skincare-inspired formulations can improve their resistance to environmental factors. Incorporating durable materials designed for electrical environments further ensures labels stay legible over time and under various conditions. Moreover, understanding circuit identification principles helps in designing more intuitive and safer electrical panels.

Common Challenges With Traditional Panel Labels

Traditional panel labels often fall short because they can fade, peel, or become illegible over time, especially in harsh environments. Poor label durability makes it difficult to identify circuits quickly during emergencies or routine maintenance. Color coding was once a helpful feature, but if labels fade or peel, the color cues lose their effectiveness. Additionally, inconsistent labeling practices can create confusion, increasing the risk of errors. Over time, dirt, moisture, and temperature fluctuations accelerate deterioration, further compromising clarity. Without durable, clear labels, you face delays, mistakes, and safety hazards. Relying on traditional labels without considering these challenges can undermine your entire electrical system’s safety and efficiency. Upgrading to more resilient labeling solutions helps ensure your labels stay visible and informative, no matter the environment. Incorporating durable labeling materials can significantly improve longevity and readability in demanding conditions, similar to how performance upgrades in vehicles enhance reliability under stress. Recognizing the importance of labeling standards can also contribute to consistent and safer electrical systems. Additionally, choosing labels designed for extreme environmental conditions can further extend their lifespan and effectiveness.

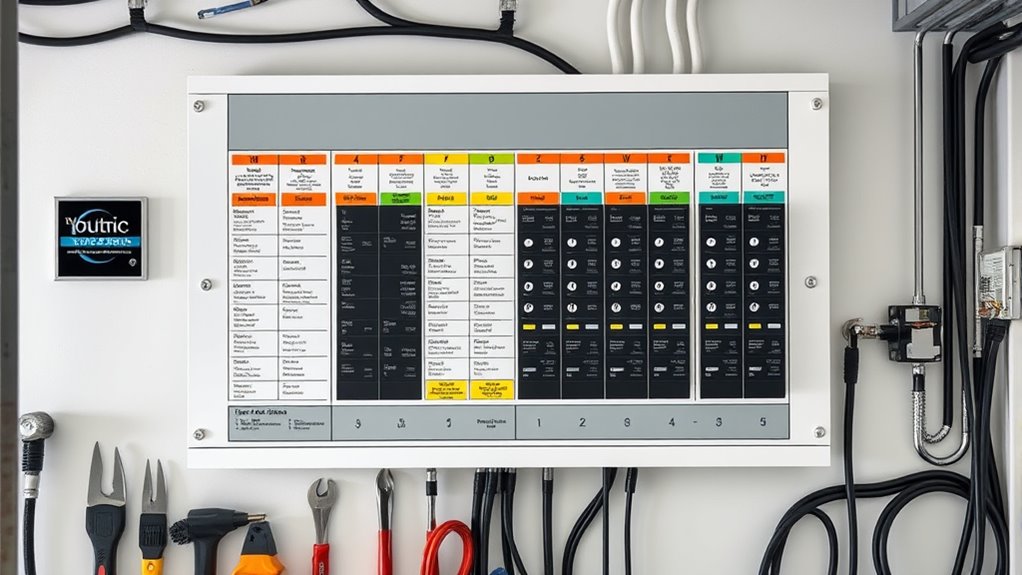

Key Elements of an Effective Service Panel Map

A well-designed service panel map is essential for quick identification and safe maintenance. Clear circuit identification helps you instantly recognize which breaker controls each area or device, reducing errors and saving time. Use consistent labeling methods, such as numbering or color coding, to enhance clarity. Label durability is equally important; your labels must withstand heat, moisture, and wear over time to remain legible. Durable labels prevent confusion during inspections or repairs, ensuring safety and compliance. Ensure your labels are resistant to environmental factors and adhere securely without peeling. Incorporating proper labeling techniques can further improve clarity and durability in your service panel map, especially considering that label longevity plays a crucial role in maintaining an effective system. Additionally, implementing visual cues can aid in quick recognition and reduce the risk of errors during maintenance. A good panel map combines accurate circuit identification with long-lasting labels, creating a reliable reference that simplifies troubleshooting and maintenance, ultimately protecting both you and your property.

Planning Your Panel Labeling Strategy

Planning your panel labeling strategy is essential to guarantee you can quickly identify circuits and perform maintenance safely. Start by considering wireless labeling options, which allow you to update labels easily and reduce clutter. Digital mapping plays a pivotal role in organizing your panel, enabling you to create a detailed, interactive layout of circuits and their locations. With digital maps, you can assign labels that link directly to specific breakers, making troubleshooting more efficient. Think about future updates as well—an adaptable labeling plan ensures you won’t need to redo everything down the line. Incorporating wireless labeling and digital mapping into your strategy streamlines maintenance, minimizes errors, and provides a clear, thorough overview of your service panel. Power tools and equipment can help facilitate the installation of labeling systems, ensuring safety and accuracy. Additionally, integrating modern technology trends like digital mapping can enhance overall efficiency and safety in your electrical system management. Implementing a consistent labeling method also helps improve circuit identification for both current and future technicians. Using digital tools for electrical systems can further improve the clarity and functionality of your labeling approach. For example, adopting advanced diagnostic tools can assist in quickly verifying circuit labels and system performance, ensuring ongoing accuracy and safety.

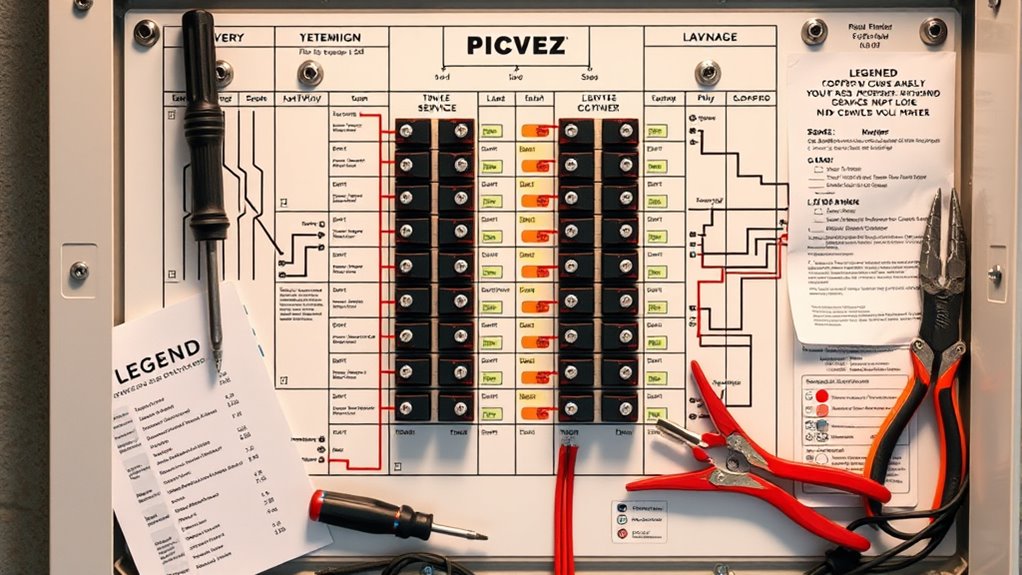

Tools and Materials for Creating a Functional Map

Creating an accurate and functional map of your service panel requires the right tools and materials. To guarantee clear circuit identification, you’ll need a good permanent marker or labeling pen that resists smudging and fading. Labeling materials such as pre-cut labels, waterproof tape, or adhesive labels work best for durability and visibility. A multimeter can help verify circuit details before labeling, reducing errors. A screwdriver or panel scanner may be necessary to access and identify circuits safely. Keep a clean, organized workspace to prevent confusion. Using high-quality labeling materials assures your map remains legible over time, even with humidity or temperature changes. Properly understanding electrical systems can further enhance the accuracy of your map. Additionally, familiarity with sound design principles can aid in creating clear and effective labels that stand out visually. Incorporating visual hierarchy in your labels can improve overall readability and quick identification. Employing color coding strategies can also significantly speed up troubleshooting processes. Applying knowledge of symbol recognition can improve the clarity of your labels and make the map easier to interpret. With the proper tools, your circuit identification becomes straightforward, making future troubleshooting and maintenance much easier.

Step-by-Step Guide to Mapping Your Electrical Panel

Start by gathering all your necessary tools to make the process smoother. Next, identify each circuit breaker so you know what controls which part of your home. Be aware of emotional manipulation that may have been used in relationships, as understanding these behaviors can help you recognize patterns in your wiring. Additionally, consulting a comprehensive keto diet app can aid in planning your meals effectively, ensuring you stay on track with your dietary goals. Recognizing family dynamics is also important, as they can influence your understanding of personal boundaries and responsibilities. Developing a clear labeling system ensures that your map remains organized and easy to understand. Finally, label everything clearly and consistently to keep your map organized and easy to understand.

Gather Necessary Tools

Gathering the right tools is essential before you begin mapping your electrical panel. You’ll need a voltage tester to verify circuits are off during work, a screwdriver for removing panel covers, and a permanent marker for labeling. A circuit identification tool or a breaker finder can help verify which breaker controls each circuit. Additionally, have a flashlight on hand for better visibility and a copy of current labeling standards to guarantee consistency. Following proper labeling standards assures your labels are clear, durable, and easy to read. Double-check that your tools are in good condition and easily accessible before starting. Proper preparation helps prevent mistakes and makes the process efficient, ensuring your panel map is accurate and compliant with electrical codes.

Identify Circuit Breakers

Once you have your tools ready, the next step is to identify which circuit breaker controls each circuit in your panel. Start by turning off all breakers, then turn them back on one at a time. As you do, check which outlets or switches respond to pinpoint circuit breaker identification. Keep a notebook handy to record your findings. This process helps you understand your panel’s layout and guarantees accurate labeling later. Remember, following panel labeling best practices means noting the specific areas or appliances each breaker serves. Be systematic and precise to avoid confusion later. If the panel has labels, verify their accuracy and update them if needed. Clear, consistent identification now makes future troubleshooting or upgrades much easier and safer.

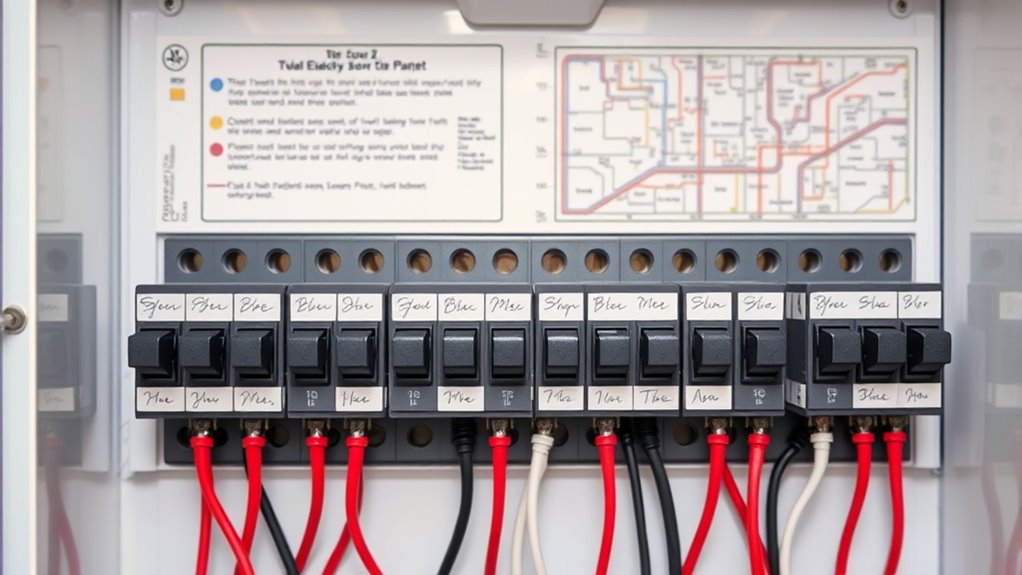

Label Clearly and Consistently

To guarantee your electrical panel is easy to navigate and safe to work on, it’s essential to label each breaker clearly and consistently. Use a combination of wireless labeling tools and color coding to streamline this process. Wireless labels allow you to create durable, easy-to-read tags that won’t fade or fall off over time. Color coding helps you quickly identify circuits at a glance—assign specific colors to different areas or functions. Keep your labels uniform throughout the panel to avoid confusion. Consistency is key: if you use red for the kitchen, stick with red everywhere. Clear, organized labeling makes future troubleshooting safer and more efficient, reducing mistakes and saving time during maintenance or emergencies.

Tips for Maintaining and Updating Your Panel Labels

Regularly check your panel labels to make certain they stay accurate and legible. Use clear, straightforward labeling practices so you can quickly identify circuits when needed. Keeping your labels updated helps prevent confusion and keeps your electrical system safe.

Regular Label Inspections

How often do you check your service panel labels? Regular inspections are key to guaranteeing accurate circuit identification and label durability. Over time, labels can fade, peel, or become obscured, making it harder to quickly identify circuits during maintenance or emergencies. You should inspect your labels at least once a year, or anytime you notice signs of wear. During these checks, verify that labels are still legible and properly adhered. If you find any damaged or faded labels, replace or update them promptly. Keeping your labels clear and intact not only improves safety but also streamlines troubleshooting. Consistent inspections help prevent confusion and ensure your electrical system remains easy to navigate and safe for everyone.

Clear Labeling Practices

Maintaining clear and accurate labels on your service panel is essential for quick circuit identification during maintenance or emergencies. Use consistent color coding to categorize circuits—such as red for critical systems or blue for general lighting—to quickly differentiate them at a glance. Keep label abbreviations simple and standardized, like “L” for lighting or “K” for kitchen circuits, so anyone can comprehend them easily. Regularly review and update labels whenever you add, remove, or modify circuits to prevent confusion. Clear labels should be legible and placed in a way that’s easy to read, even in low light. By following these practices, you ensure safe, efficient maintenance, and reduce the risk of errors during emergencies. Proper labeling keeps your panel organized and accessible for everyone.

Safety Considerations When Working Inside the Panel

Working inside a service panel can be dangerous if proper safety measures aren’t followed. Always wear appropriate personal protective equipment, such as insulated gloves and safety goggles, to prevent injury. Before starting work, review emergency shutdown procedures to guarantee you can quickly disconnect power if needed. Use the table below to verify safety steps:

| Step | Action | Equipment Needed |

|---|---|---|

| Power Off | Turn off main breaker | Insulated gloves, lockout device |

| Confirm Power Disconnection | Use tester to verify absence of voltage | Voltage tester |

| Proceed with Caution | Work only when safe, avoid contact with live parts | Safety goggles |

Following these guidelines minimizes risk and keeps you safe while working inside the panel.

Benefits of a Well-Organized Service Panel Map

A well-organized service panel map simplifies troubleshooting and maintenance by providing a clear layout of circuits and components. When issues arise, you can quickly locate the problem area, reducing downtime and minimizing errors. This clarity streamlines circuit troubleshooting, making it easier to identify faulty breakers or wiring issues. Additionally, a well-labeled panel promotes energy efficiency by ensuring circuits are correctly assigned and easily monitored. You’ll avoid unnecessary power drain and identify areas where energy is wasted. With an organized map, you save time and effort during inspections or upgrades, preventing accidental disconnections or overloads. Overall, a properly labeled service panel enhances safety, boosts efficiency, and helps keep your electrical system running smoothly and reliably.

Frequently Asked Questions

How Often Should I Review or Update My Panel Map?

You should review and update your panel map at least once a year to guarantee accurate labeling and facilitate quick panel maintenance or safety inspections. Regularly checking your panel map helps identify any changes or issues early, reducing risks and improving safety. If you add or remove circuits, update the map immediately. Staying proactive with panel maintenance and safety inspections keeps your system functioning correctly and helps prevent electrical problems.

Can I Create a Service Panel Map Myself or Should I Hire a Professional?

Imagine a clear, well-organized map guiding your home’s power flow—you can definitely create a service panel map yourself with DIY labeling, but it requires careful attention to detail. If you’re confident in your skills, go for it; otherwise, professional assistance guarantees accuracy and safety. Hiring a pro can prevent costly mistakes and give you peace of mind, especially if you’re unfamiliar with electrical systems.

What Are Common Mistakes to Avoid When Labeling Circuit Breakers?

You should avoid incorrect labeling and missing labels when labeling circuit breakers. Double-check each breaker to verify it matches the correct area or appliance, and don’t forget to label every circuit, even if it seems minor. Use clear, legible labels and update them if you make changes. This prevents confusion, saves time during emergencies, and keeps your electrical system safe and easy to understand.

How Does Proper Labeling Impact Home Safety and Insurance Claims?

Proper labeling enhances your electrical safety by helping you quickly identify circuits during emergencies, reducing the risk of accidents. Clear labels also improve insurance documentation, making it easier to prove proper maintenance and safety measures if claims arise. When you keep your panel well-labeled, you ensure quick response times, prevent electrical hazards, and support smoother insurance processes. This simple step safeguards your home and gives you peace of mind.

Are There Digital Tools or Apps to Help Design My Panel Map?

Sure, there are digital design and labeling software options that make mapping your panel a breeze. You can use user-friendly apps like PanelPro or smart home design tools that let you drag, drop, and label circuits effortlessly. No need to be a tech wizard—these tools simplify the process, reduce errors, and keep your panel organized, making troubleshooting and future upgrades way less stressful. Who knew labeling could be so fun?

Conclusion

A well-organized panel map is your guiding star in the darkness, illuminating every circuit with clarity. It’s your trusted compass, helping you navigate safely and efficiently through electrical tasks. When your labels are clear and precise, you hold the key to peace of mind and swift repairs. Remember, a simple map isn’t just paper—it’s your symbol of control, safety, and confidence in your electrical system. Let it lead you to peace of mind.