Grounding connects electrical systems to Earth, providing a safe path for fault currents and preventing voltage buildup, while bonding links conductive metal parts to maintain a uniform potential, reducing shock risks. The critical rule is that grounding offers an earth reference for fault clearing, whereas bonding keeps all metal parts at the same voltage without creating a direct earth connection. Understanding this difference is essential for safety—and if you keep exploring, you’ll learn how to apply these principles effectively.

Key Takeaways

- Grounding provides a direct path to earth to safely carry fault currents away.

- Bonding connects conductive parts to maintain equal potential and prevent voltage differences.

- The critical rule is that grounding handles fault current flow to earth, bonding ensures metal parts stay at the same potential.

- Proper grounding prevents dangerous voltage buildup, while bonding reduces shock risks by ensuring continuous electrical potential.

- Misunderstanding the roles can lead to safety hazards; both are essential but serve distinct purposes in shock prevention.

Understanding the Purpose of Grounding and Bonding

Have you ever wondered why grounding and bonding are essential in electrical systems? They play a vital role in circuit protection by providing a safe path for fault currents. Equipment grounding connects electrical devices to the earth, helping to prevent electric shocks and damage. When a fault occurs, the grounding system guarantees that excess current safely flows into the ground, reducing the risk of injury or fire. Bonding, on the other hand, links conductive parts to maintain a continuous electrical path, preventing potential differences that could cause shocks. Together, grounding and bonding enhance safety, ensuring that any stray or fault current is swiftly directed away from people and equipment. Proper safety standards and adherence to regulations are crucial in designing and maintaining effective grounding and bonding systems. Establishing a reliable electrical system involves careful planning of grounding and bonding practices to ensure ongoing safety and compliance. This foundation of safety is crucial for reliable, secure electrical systems.

The Key Difference Between Grounding and Bonding

The primary difference between grounding and bonding lies in their specific functions within an electrical system. Grounding provides a safe path for fault current to reach the earth, helping prevent shocks and equipment damage. Bonding, on the other hand, connects conductive parts to guarantee they stay at the same electrical potential, avoiding dangerous voltage differences. Many grounding misconceptions exist, such as believing grounding alone prevents shocks, which isn’t true; it’s part of a complete safety system. Bonding myths also circulate, like thinking bonding creates a shock hazard—actually, it reduces the risk by equalizing potential. Understanding this key distinction is vital for proper system design and safety. Proper safety procedures help ensure that electrical systems operate safely and effectively, reducing the risk of accidents. Signs of spoilage such as off-smell and discoloration are important indicators of unsafe lemon juice. Additionally, correct installation practices ensure that grounding and bonding are correctly implemented to maximize safety. Recognizing that grounding and bonding serve different but complementary roles helps in designing safer electrical systems. It is also essential to recognize that certifications and endorsements from trusted safety organizations can verify that systems are properly designed and maintained. By clarifying these roles, you confirm your electrical setup adheres to safety standards and avoids common errors.

How Grounding Protects Against Faults

Grounding plays a crucial role in protecting your electrical system against faults by providing a direct, low-resistance path for fault current to reach the earth. Proper grounding techniques ensure that in the event of a fault, excess current flows safely away from you and your devices, minimizing shock risks. This process helps prevent electrical fires and damage by quickly clearing faults through the circuit breaker. Bonding methods complement grounding by connecting metallic parts to the grounding system, reducing voltage differences that could cause shocks. Together, effective grounding techniques and bonding methods ensure that when a fault occurs, the electrical system directs the current safely into the ground, protecting you from potential electrocution and maintaining overall safety. Additionally, understanding electrical safety principles is essential for designing and maintaining safe electrical systems. Proper grounding also involves ground resistance testing to confirm that the system is functioning correctly and providing adequate protection in all conditions. Incorporating grounding system maintenance checks regularly helps identify potential issues before they lead to hazards.

The Role of Bonding in Electrical Safety

Bonding guarantees electrical continuity by connecting all metal parts, reducing the risk of shock hazards. It also helps manage fault currents, allowing protective devices to trip quickly. By doing so, bonding plays a vital role in maintaining safety during electrical faults. Proper custodian services are essential for ensuring the integrity of grounding and bonding systems, especially in complex electrical installations. Additionally, regular inspections ensure that bonding systems remain effective over time, preventing potential safety issues. Understanding cost variances can help optimize maintenance and safety investments in electrical systems. Furthermore, understanding grounding and bonding principles is crucial for designing compliant and safe electrical systems.

Ensuring Electrical Continuity

Maintaining continuous electrical connections is crucial for safety and system reliability. Proper bonding ensures a low-resistance path, which helps in effective circuit protection by quickly clearing faults. This continuous connection prevents potential differences that could cause shocks or equipment damage. You should verify bond integrity regularly, especially in critical systems. Insulation methods alone don’t guarantee electrical continuity, so bonding provides an essential backup. When bonding is intact, it maintains a reliable conductive path, ensuring that fault currents flow safely to ground. This reduces the risk of shock hazards and equipment failure. Additionally, sound engineering practices support the effectiveness of bonding in safeguarding electrical systems. By keeping bonds intact and functioning correctly, you create a safer environment and improve the overall performance of your electrical system. Proper bonding is a key element in achieving consistent electrical continuity, which is vital for system safety and efficiency. Regular inspection and testing of bonds are recommended to maintain electrical safety standards, as they help prevent unexpected failures. Ensuring **bond integrity** is part of a comprehensive approach to electrical safety. Implementing these practices can also prevent damage caused by high-pressure surges or electrical faults, further emphasizing the importance of reliable connections in electrical safety protocols.

Preventing Shock Hazards

Have you ever wondered how electrical systems prevent shocks and protect people from harm? Many believe grounding myths suggest that simply grounding a system avoids all shock risks, but that’s not true. Bonding myths also circulate, implying that bonding alone eliminates shock hazards. In reality, bonding creates a low-resistance path that helps guarantee fault currents flow safely back to the source, reducing shock risk during faults. Proper bonding and grounding work together to prevent dangerous voltage differences that could cause shocks. Without correct bonding, even grounded systems can pose shock hazards if faults occur. Additionally, proper insulation helps further prevent electrical shocks by keeping current confined within designated pathways. This synergy between bonding and grounding enhances overall electrical safety and reduces the potential for shock hazards. Understanding the role of bonding and grounding in electrical safety is crucial for preventing shocks and ensuring safe system operation. Proper installation practices and adherence to electrical codes are vital for maintaining effective grounding and bonding systems. By understanding these myths, you can better appreciate how bonding plays a critical role in electrical safety and shock prevention.

Managing Fault Currents

Managing fault currents is crucial for ensuring electrical safety, especially when a system experiences a short circuit or insulation failure. Proper bonding helps direct fault currents safely to the ground, minimizing shock risks and equipment damage. Beware of grounding myths that suggest grounding alone prevents shocks; bonding is equally essential. Avoid bonding misconceptions that imply it’s optional—it’s fundamental for safe fault path creation. When fault currents flow correctly through bonded paths, circuit breakers trip quickly, reducing hazards. Here are key points:

- Bonding creates a low-resistance path for fault currents

- Proper bonding reduces the chance of electric shock

- Grounding myths often overlook the importance of bonding

- Bonding misconceptions can compromise safety

- Regular inspections ensure bonding effectiveness

- Incorporating fault current management practices can promote overall system reliability and safety.

Understanding these concepts helps you prevent dangerous faults and protect everyone.

The Critical Rule That Distinguishes Grounding From Bonding

Understanding the critical difference between grounding and bonding hinges on a simple but essential rule: grounding connects electrical systems to the earth to provide a safe path for fault currents, while bonding links conductive parts together to guarantee they remain at the same potential. This rule helps you avoid grounding misconceptions, such as thinking grounding and bonding are interchangeable. It also clears up bonding myths that suggest bonding alone prevents shocks; in reality, bonding ensures all metal parts are at the same voltage but doesn’t provide a direct path to earth. Recognizing this distinction is crucial for safety. Proper grounding prevents dangerous voltage buildup, while bonding maintains uniform potential across system components, reducing shock risks. This rule forms the foundation for correct electrical safety practices.

Common Mistakes Caused by Confusing Grounding and Bonding

When you confuse grounding with bonding, you risk making critical wiring mistakes that compromise safety. Mixing up their purposes can lead to improper connections and dangerous conditions. Overlooking standards only increases the chance of accidents and system failures.

Mixing Up Purposes

One common mistake electricians make is confusing the purposes of grounding and bonding, which can lead to serious safety issues. This often stems from grounding myths and bonding misconceptions, where people think they’re interchangeable. Mixing them up can cause shock hazards or equipment damage. For example, assuming grounding prevents all faults is wrong; it’s the bonding that ensures metal parts stay at the same potential. Misunderstanding these roles can lead you to improperly connect systems, risking electrical shock.

- Believing grounding and bonding serve the same function

- Thinking grounding alone prevents shocks

- Assuming bonding is only for lightning protection

- Confusing grounding wire with neutral wire

- Overlooking the importance of proper bonding in panels

Incorrect Wiring Practices

Incorrect wiring practices often happen when electricians confuse grounding and bonding, leading to dangerous mistakes. Poor circuit design can result in improper connections, causing shocks or equipment damage. For example, misplacing grounding conductors or neglecting proper insulation techniques can create unintended current paths. Confusing grounding with bonding may lead you to connect grounding wires where bonding should be, or vice versa, jeopardizing safety. You might also overlook the importance of correct insulation, which prevents accidental contact with live parts. These errors compromise the system’s ability to safely divert faults and can cause electrical shocks. To avoid these mistakes, always understand the distinct roles of grounding and bonding, follow proper circuit design principles, and guarantee insulation techniques are correctly applied during installation.

Overlooking Safety Standards

Failing to adhere to safety standards often stems from confusing grounding with bonding, which can lead electricians to make critical errors. Many fall for grounding myths, believing it prevents shocks, or buy into bonding myths that it fixes all electrical issues. This confusion causes overlooked safety protocols and risky installations. You might think that simply bonding a metal part is enough, or that grounding eliminates all hazards. But safety standards clarify that grounding and bonding serve different purposes and must be implemented correctly. Ignoring these distinctions increases the risk of electrical shock or fire. To stay safe, you need to understand these differences clearly, avoid common misconceptions, and follow established guidelines. Proper grounding and bonding are essential for safety, not optional or interchangeable solutions.

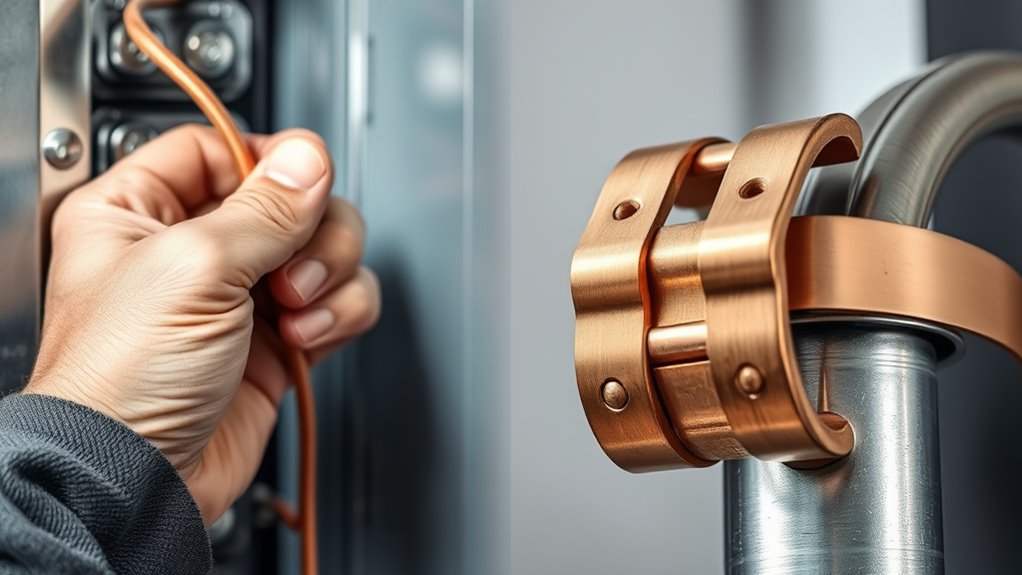

Practical Examples of Proper Grounding and Bonding

Proper grounding and bonding are essential for ensuring electrical safety and equipment protection in real-world settings. For example, when installing a new electrical outlet, you connect the grounding wire to the ground bus bar, creating a reliable path for fault currents—this is equipment grounding. Similarly, in industrial setups, you bond metal equipment frames to the grounding system to prevent voltage buildup. This electrical bonding ensures that all metal parts stay at the same electrical potential, reducing shock risks. In outdoor lighting, grounding stakes are driven into the earth, providing a safe dissipation route for stray currents. These practical applications demonstrate how proper grounding and bonding work together to protect both people and equipment from electrical hazards.

Ensuring Safety by Following the Correct Electrical Practices

When you implement correct electrical practices, you’re taking essential steps to protect yourself and others from potential hazards. Proper grounding, bonding, and adherence to safety protocols reduce the risk of electrical shocks and fires. Focus on lightning protection measures to prevent damage during storms and ensure electrical insulation to keep live wires contained. Regular inspections help identify issues early, while using quality materials guarantees durability. Always turn off power before working on circuits, and follow local codes and standards. Educate yourself on safe electrical practices to make informed decisions. Remember, safety is a shared responsibility that depends on consistent, correct procedures. Staying vigilant and proactive minimizes risks, creating a safer environment for everyone around you.

- Use proper lightning protection systems during storms

- Regularly check electrical insulation of wires and devices

- Follow local electrical codes and safety standards

- Turn off power before performing any electrical work

- Keep your work area dry and free of moisture

Frequently Asked Questions

Can Grounding and Bonding Be Used Interchangeably in Electrical Systems?

You can’t use grounding and bonding interchangeably in electrical systems because each plays a distinct role in electrical safety and system reliability. Grounding provides a safe path for fault currents, protecting you from shocks, while bonding ensures all metal parts are connected to prevent voltage differences. Using them correctly enhances electrical safety and system reliability, reducing shock risks and preventing equipment damage. Always follow code requirements to guarantee proper grounding and bonding practices.

What Are the Consequences of Improper Grounding or Bonding?

Ironically, neglecting proper grounding and bonding can turn your electrical safety into a shocking surprise. When you skip these steps, you risk electrical shocks, equipment damage, and fire hazards. You might think you’re safe, but improper grounding or bonding compromises shock prevention, putting everyone at risk. Always make certain your system is correctly grounded and bonded to protect yourself and others from dangerous electrical faults. Safety depends on proper wiring practices.

How Often Should Grounding and Bonding Systems Be Inspected?

You should inspect your grounding and bonding systems at least once a year as part of your maintenance schedule. Regular inspections help make certain they remain effective and compliant with safety standards. If you operate in harsh environments or see signs of damage, increase inspection frequency to every six months. These routine checks prevent shocks and electrical hazards, keeping your system safe and reliable for long-term use.

Are There Specific Codes Governing Grounding and Bonding Practices?

Yes, there are specific codes governing grounding and bonding practices. You must follow the National Electrical Code (NEC) to guarantee code compliance and meet safety standards. Imagine the critical moment when a faulty connection could cause a shock—strict codes exist to prevent that. Staying updated with these regulations not only keeps you compliant but also protects lives. Ignoring them risks both safety and legal consequences, so always adhere to proper grounding and bonding procedures.

What Materials Are Best Suited for Effective Grounding and Bonding?

You should use metallic conductors like copper or aluminum for effective grounding and bonding since they’re highly conductive. Conductive materials such as copper wire, grounding rods, and metal conduit are ideal because they provide low resistance paths for electrical currents. Copper is preferred due to its excellent conductivity and durability, ensuring safety and reliable electrical connections. Always select materials that meet local codes and standards for maximum protection.

Conclusion

Remember, grounding and bonding are your shields against electrical shocks, like the roots and branches of a mighty tree. By understanding their distinct roles, you guarantee safety flows smoothly through your home, much like a river finds its course. Keep these principles clear in your mind, and you’ll prevent hazards from lurking in the shadows. Stay vigilant, and let these electrical safeguards stand as silent guardians, protecting you and your loved ones from unseen dangers.