To reduce flicker caused by motor loads, you can install simple passive filters that include inductors and capacitors to smooth voltage fluctuations. These filters absorb or counteract rapid changes when motors start or operate under heavy loads, stabilizing the voltage supply to lighting circuits. Choosing the right filter depends on your system’s needs and budget. If you want to learn more about effective solutions, keep exploring how simple filters can improve your power quality.

Key Takeaways

- Passive filters with inductors and capacitors can smooth voltage fluctuations caused by motor starting.

- Installing simple line reactors or chokes reduces inrush current and voltage dips during motor startup.

- Properly sized filters help stabilize voltage supplied to lighting circuits affected by motor flicker.

- Using soft starters minimizes motor inrush current, decreasing flicker severity on connected loads.

- Combining filters with improved wiring and load balancing enhances overall power quality and flicker mitigation.

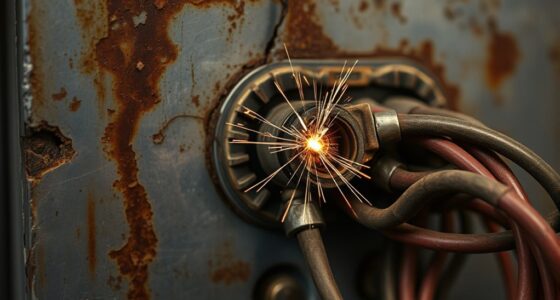

Flicker from motor loads occurs when large or frequently starting motors cause fluctuations in electrical voltage, leading to visible light flickering in connected lighting systems. This flickering is a common power quality issue that can disrupt operations, cause discomfort, and even damage sensitive equipment. Understanding how motor loads impact power quality is essential for identifying effective mitigation techniques to reduce flicker and maintain a stable electrical environment.

Motor starting and operation can cause voltage fluctuations leading to flickering lights and equipment issues.

When motors start up or operate under heavy loads, they draw a surge of current that temporarily drops the voltage levels in the system. This voltage dip causes the lighting connected to the same circuit to flicker because the lights rely on stable voltage levels for consistent brightness. The extent of flicker depends on factors like the size of the motor, the wiring configuration, and the overall power system design. If left unaddressed, these voltage fluctuations can become persistent, degrading power quality and complicating the operation of other electrical devices.

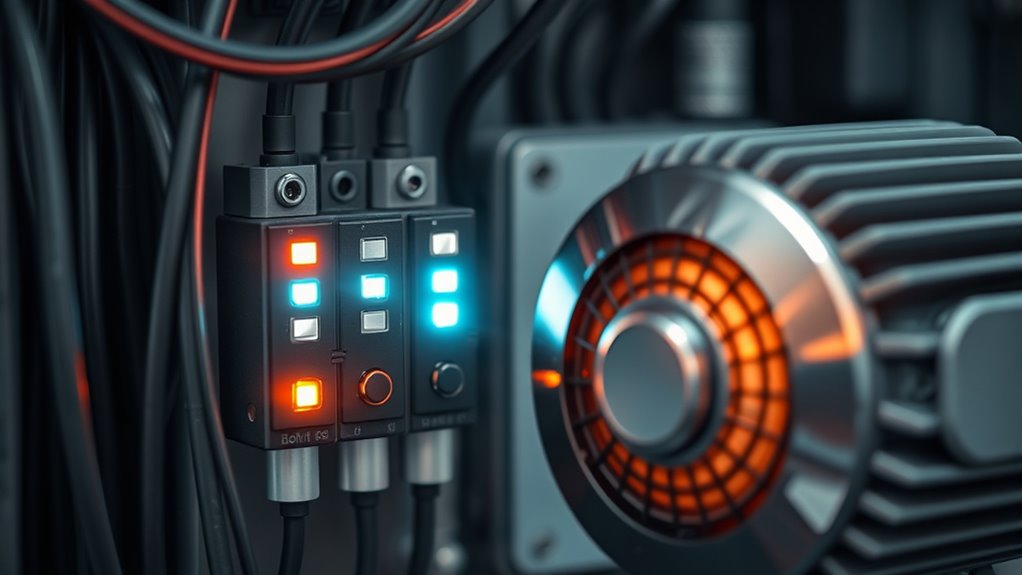

To combat flicker caused by motor loads, you can implement various mitigation techniques focused on improving power quality. One effective approach is installing simple filters that smooth out voltage variations. These filters, such as passive or active power filters, help absorb the sudden changes in current and stabilize the voltage supplied to lighting circuits. Passive filters, which typically include inductors and capacitors, are cost-effective and straightforward to install, making them suitable for many industrial and commercial settings. Active filters, on the other hand, use power electronics to dynamically counteract voltage fluctuations and offer a higher level of control, although they tend to be more complex and expensive.

Another useful mitigation technique involves adjusting the motor’s starting methods. Instead of direct-on-line startup, which causes a significant inrush current, you can opt for soft starters or variable frequency drives (VFDs). These devices gradually ramp up the motor speed, reducing the initial current surge and minimizing voltage dips that lead to flicker. Additionally, balancing the electrical load across phases and ensuring proper wiring can improve overall power quality, reducing the likelihood of flicker from motor loads. Proper wiring and load balancing are crucial for maintaining stable voltage levels and preventing flickering issues.

Frequently Asked Questions

How Do Motor Load Variations Affect Flicker Severity?

Motor load variations increase flicker severity by causing rapid power quality fluctuations. When your motor load fluctuates, it leads to voltage dips and surges, affecting the stability of the electrical system. These load fluctuations create inconsistent power quality, making flicker more noticeable and disruptive. To minimize this, consider installing simple filters that stabilize voltage, reduce flicker, and improve overall power quality during motor load changes.

Can Flicker Filters Be Integrated Into Existing Electrical Systems Easily?

Fast and flexible, filter integration is generally straightforward, making retrofit options quite feasible. You can easily incorporate simple filters into your existing electrical systems without extensive overhauls. Many filters are designed for easy installation, allowing you to upgrade your setup swiftly and smoothly. With minimal modifications, you can markedly reduce flicker and improve power quality, ensuring your system stays stable and sound without disrupting your current operational routine.

What Maintenance Is Required for Flicker Mitigation Devices?

You need to regularly check your flicker mitigation devices, focusing on sensor calibration to make certain of accurate performance. Keep an eye on the device’s components for wear and tear, and clean any dust or debris that could affect operation. Proper maintenance promotes device longevity, reduces false triggers, and maintains flicker mitigation effectiveness. Schedule periodic inspections based on manufacturer recommendations to guarantee your system continues to run smoothly and efficiently.

Are There Specific Motor Types More Prone to Causing Flicker?

Think of some motors as the drama queens of your electrical system—they tend to cause more flicker. You’re more likely to see flicker from motors during startup or when running variable speed drives. These motor types draw large inrush currents, making them more prone to causing voltage fluctuations. To keep flicker at bay, consider installing simple filters, especially on high-startup and variable speed motors.

How Does Ambient Temperature Influence Flicker Mitigation Effectiveness?

Ambient temperature considerably influences flicker mitigation effectiveness because higher temperatures can reduce motor cooling efficiency, leading to increased load fluctuations and flicker. When the environment maintains good ambient cooling and temperature stability, filters work more effectively, minimizing flicker. Conversely, temperature swings can impair filter performance, making it harder to control flicker. Ensuring ideal ambient conditions supports consistent filter operation and helps reduce flicker caused by motor loads.

Conclusion

By implementing simple filters, you tame the flicker like a steady hand guiding a flickering candle, restoring calm to your power system. These filters act as a beacon of stability, transforming restless motor loads into a gentle, predictable glow. With each quieted flicker, you restore harmony, ensuring your electrical environment remains a steadfast lighthouse amid turbulent currents. Embrace these solutions, and let your system shine steady and true, unwavering in its silent promise of reliability.