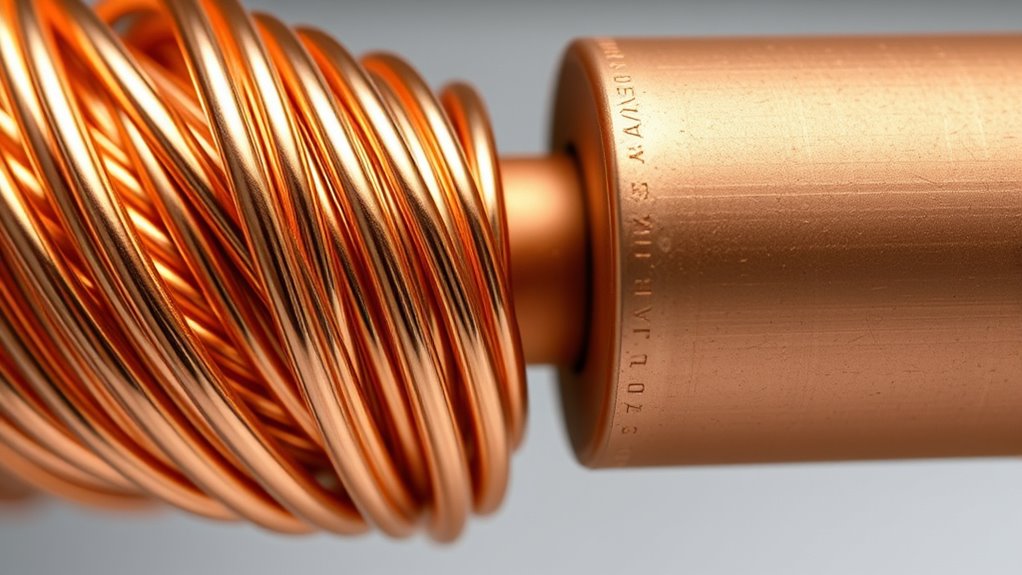

If you’re wondering which wire bends easily and which holds its shape, stranded wires are your answer—they’re flexible and can bend easily to fit tight spaces or curves. Solid wires, on the other hand, are rigid and maintain their shape, making them ideal for fixed, stable connections. Understanding these differences helps you choose the right type for your project. Keep exploring to see how each type performs in different applications.

Key Takeaways

- Stranded wires are more flexible and bend easily, making them ideal for applications requiring frequent movement.

- Solid wires are rigid and hold their shape well, suitable for fixed, long-term installations.

- Stranded wires resist fatigue and breakage under bending or twisting, enhancing durability in dynamic environments.

- Solid wires maintain stable connections over time in static setups with minimal bending.

- The choice depends on whether the wiring needs to bend or stay securely in place.

When choosing electrical wiring, understanding the differences between stranded and solid wire is essential for ensuring safety and performance. Each type has unique qualities that make it better suited for specific applications, so knowing how they compare can help you make informed decisions. One key aspect to weigh up is corrosion resistance. Stranded wires tend to be more resistant to corrosion because their multiple strands provide better flexibility and surface area, which can help prevent corrosion from environmental factors like moisture and air exposure. Solid wires, on the other hand, are more vulnerable to corrosion since their single conductor is less exposed to external elements, especially when the insulation is compromised. This makes stranded wiring a better choice for outdoor or damp environments where corrosion could compromise safety and conductivity over time. Additionally, the age of the unit can influence how likely a wire is to fail, with older systems being more susceptible to issues such as corrosion and mechanical wear. Ease of installation is another critical factor. Solid wires are generally easier to install in fixed positions because their rigidity allows them to hold their shape, making it simpler to push them into terminals or conduit without much fuss. They’re often used in applications where they won’t need to be moved frequently, like in wall outlets or switches. Stranded wires, however, are more flexible and easier to manipulate when you’re working in tight or complex spaces. Their flexibility allows you to navigate around obstacles and make secure connections in crowded electrical boxes. This ease of installation becomes particularly advantageous in projects requiring frequent adjustments, or when wiring needs to bend around corners and tight spaces. You should also think about how each type performs under stress. Stranded wires are more forgiving when it comes to bending and twisting, which reduces the risk of breakage or fatigue over time. This makes them ideal for applications where the wire will experience movement or vibration. Solid wires, while less flexible, provide a more stable and consistent connection in static setups, where minimal movement is expected. If your project involves frequent adjustments or requires flexible runs, stranded wire is likely your best bet. Conversely, for long-term, fixed installations, solid wire offers a straightforward, durable solution.

Frequently Asked Questions

Which Wire Type Is More Resistant to Corrosion?

You’ll find that stranded wire generally offers better corrosion resistance and environmental durability compared to solid wire. Its multiple strands are often coated with protective materials, making it more resistant to moisture and environmental factors. This flexibility also helps prevent damage that can expose the metal to corrosion. So, if you need a wire that stands up well to harsh conditions, stranded wire is your best choice for durability and long-term resistance.

How Does Wire Flexibility Affect Installation Speed?

Your wire flexibility directly impacts installation speed and ease. Flexible wires, like stranded ones, bend easily, reducing the time needed for routing and fitting, especially in tight spaces. Less flexible, solid wires resist bending, making installation more cumbersome. While wire tensile strength ensures durability, flexibility allows you to work faster and more efficiently. Opt for flexible wiring when quick, straightforward installation is a priority, saving you time and effort.

Can Stranded Wire Be Used for High-Frequency Applications?

Yes, stranded wire can be used for high-frequency applications, but you need to contemplate wire gauge differences and signal integrity. Stranded wire offers flexibility, reducing signal loss and interference, which benefits high-frequency use. However, thinner gauges may impact signal quality, so choose appropriately. You’ll find that stranded wire maintains flexibility while supporting efficient signal transmission, making it suitable for high-frequency tasks if you pay attention to gauge and shielding.

What Safety Precautions Are Necessary When Handling Both Wire Types?

When handling both wire types, you should wear gloves to prevent cuts and guarantee insulation compatibility. Use proper handling techniques, like avoiding excessive bending or pulling, to maintain safety and wire integrity. Always check insulation for damage before working, and keep your workspace dry to prevent electrical hazards. Properly securing the wires during installation also minimizes risks, ensuring safe and reliable connections.

How Do Cost Differences Impact Long-Term Electrical Projects?

Imagine your project’s budget as a tightrope—you need balance. Cost differences substantially impact long-term electrical projects; stranded wire often costs more upfront but offers better flexibility, reducing labor and replacement costs over time. Solid wire is cheaper initially but may require more frequent repairs, increasing expenses. To guarantee cost efficiency, consider how wire choice affects project budgeting, balancing initial costs with long-term reliability and maintenance needs.

Conclusion

So, when you’re choosing between stranded and solid wire, picture yourself as the conductor of a delicate dance. Stranded wire bends gracefully like a flowing river, adapting effortlessly around corners. Solid wire stands firm and steady, like a sturdy tree trunk, holding its ground. Your choice depends on whether you need flexibility or strength—each wire type playing its part in your electrical symphony, shaping the flow of energy with purpose and precision.