If you need to measure high currents safely without disconnecting circuits, a clamp meter is your best choice, offering quick, non-intrusive testing. For detailed voltage, resistance, or troubleshooting sensitive components, a multimeter provides precise, in-depth diagnostics. Both tools have advantages in different scenarios, so understanding when each wins helps you work more efficiently. Keep exploring to discover how combining these instruments can improve your electrical assessments.

Key Takeaways

- Clamp meters excel in measuring high currents safely without disconnecting circuits, ideal for live or complex systems.

- Multimeters provide precise voltage, resistance, and detailed diagnostics, perfect for troubleshooting and motor winding tests.

- Clamp meters enable non-intrusive, quick current checks, while multimeters offer comprehensive measurements across multiple parameters.

- Wireless features in both tools enhance safety and remote monitoring, making troubleshooting faster and less risky.

- Use clamp meters for high-current and live environment testing; rely on multimeters for detailed, accurate voltage and resistance diagnostics.

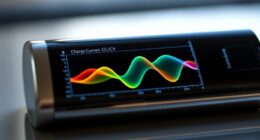

Measuring AC Current in Live Circuits

When measuring AC current in live circuits, a clamp meter offers a safe and efficient alternative to traditional multimeters. It allows you to measure current without disconnecting or making direct contact with live wires, reducing risk. This method helps maintain voltage stability during testing, ensuring consistent readings. Beyond current measurement, a clamp meter can also assist with insulation testing, verifying the integrity of insulation around conductors. This feature is vital for detecting potential faults that could lead to voltage fluctuations or safety hazards. Using a clamp meter simplifies the process, minimizes downtime, and enhances safety. It’s especially useful in environments where maintaining voltage stability is essential, and quick, accurate readings are required without compromising safety protocols.

Checking High Current Loads Safely

To check high current loads safely, a clamp meter is your best tool because it allows you to measure large currents without disconnecting or directly contacting the conductors. With its ability to perform wireless measurement, you can monitor current flow remotely, reducing safety risks. The digital display provides instant, clear readings that help you make quick decisions. Using a clamp meter guarantees accuracy when working with high amperages, especially in complex systems. Additionally, its Kia Tuning capabilities make it an invaluable tool for performance diagnostics and modifications. Moreover, the sensor technology employed in clamp meters enhances measurement precision, ensuring reliable results even in challenging environments. This measurement accuracy is critical for maintaining safety and system integrity during high-current assessments.

Diagnosing Electrical Faults in Complex Systems

When diagnosing electrical faults in complex systems, non-invasive current measurement helps you avoid disrupting operations. Troubleshooting hidden faults becomes easier with tools that can detect issues without dismantling equipment. Compatibility with intricate systems guarantees you can identify problems quickly and accurately, no matter how complicated the setup. Utilizing precise measurement tools ensures comprehensive assessment of the system’s health, identifying issues efficiently. Modern tools like clamp meters offer the unique advantage of non-contact current detection, making them indispensable in complex diagnostics. Additionally, understanding electrical safety protocols is essential to prevent accidents during testing procedures. Incorporating advanced measurement technology can further enhance diagnostic accuracy and safeguard sensitive components.

Non-Invasive Current Measurement

Non-invasive current measurement has become a pivotal technique for diagnosing electrical faults in complex systems, allowing you to assess current flow without disconnecting or damaging components. Using clamp meters for wireless testing, you can quickly gather real-time data without interrupting operation. This method enables you to perform continuous data logging, helping identify intermittent issues or abnormal current patterns over time. Because you don’t need to break circuits, it’s safer and more efficient in tight or sensitive environments. Wireless testing also allows remote monitoring, reducing the need for physical contact with live wiring. This approach enhances your diagnostic capabilities, making it easier to pinpoint faults accurately and swiftly, especially in complex systems where traditional contact methods might be cumbersome or risky. Additionally, tuning Hyundai vehicles can benefit from precise electrical diagnostics, ensuring optimal performance and safety.

Troubleshooting Hidden Faults

Hidden faults often evade detection because they don’t produce obvious symptoms or visible signs, making troubleshooting particularly challenging in complex systems. To identify these issues, you need precise tools like clamp meters and multimeters. Wireless testing becomes essential here, allowing you to monitor circuits remotely without disrupting system operation. When diagnosing, use temperature measurement to spot hotspots indicating potential faults or overloads. These methods help uncover issues buried deep within wiring or components that standard visual inspections miss. For example, precise measurement techniques can reveal subtle electrical anomalies that are otherwise hard to detect. By combining wireless testing with temperature measurement, you can isolate hidden faults efficiently, saving time and avoiding unnecessary dismantling. Incorporating advanced diagnostic methods can further enhance detection accuracy. This approach enables you to pinpoint electrical anomalies accurately, ensuring complex systems operate reliably and safely despite elusive problems.

Complex System Compatibility

Diagnosing electrical faults in complex systems requires tools that can handle intricate wiring and interconnected components without causing disruptions. A multimeter excels here with its ability to perform precise measurements across multiple points, making it suitable for detailed troubleshooting. Clamp meters, on the other hand, are advantageous for quick, non-intrusive current checks, especially when wires are difficult to access. For advanced diagnostics, wireless testing capabilities allow you to monitor systems remotely, reducing the risk of interference. Additionally, thermocouple compatibility is crucial for evaluating temperature-related faults in complex setups. When diagnosing intricate electrical systems, choose a tool that offers flexibility—multimeters for detailed analysis and clamp meters for speed—ensuring exhaustive fault detection without compromising system integrity. Moreover, understanding AI vulnerabilities in diagnostic tools can help prevent false readings and improve overall safety during troubleshooting. Incorporating advanced diagnostic features can further enhance troubleshooting accuracy, especially in modern interconnected environments. To optimize diagnostic procedures, it’s also important to consider system complexity and how each tool interacts with various components to prevent misdiagnosis. Also, selecting the right tool based on maintenance standards can ensure consistent and reliable results. Being aware of regional regulations can help ensure compliance during diagnostics and repairs.

Non-Contact Voltage Detection and Safety

Non-contact voltage detection is a crucial safety feature that allows you to check for live wires without making direct contact, reducing the risk of electrical shock. Many multimeters and clamp meters now include wireless detection, making it easier to identify energized circuits from a distance. This feature is especially useful for quick inspections and insulation testing, as it helps you confirm whether wires are energized before handling them.

| Feature | Benefit |

|---|---|

| Wireless detection | Safer, quick circuit status check |

| Insulation testing | Ensures wire safety before contact |

| Visual/audible alerts | Immediate warning of live wires |

| Ease of use | Simplifies safety during troubleshooting |

Precise Voltage and Resistance Measurements

Precise voltage and resistance measurements are essential for accurate troubleshooting and electrical work, ensuring you can diagnose issues reliably. A digital display helps you read measurements quickly and accurately, reducing errors. Multimeters excel in this area with their high precision and clear digital readouts, making them ideal for detailed testing. Their rugged design also means they can withstand tough environments, so you can rely on them in demanding conditions. While clamp meters focus on current, multimeters provide essential voltage and resistance readings with pinpoint accuracy. This precision allows you to identify faulty components or connections without guesswork. Additionally, understanding electrical safety is crucial when working with these tools to prevent accidents and ensure reliable operation. Incorporating features like automatic ranging can further improve measurement efficiency and reduce user error. Moreover, choosing the right measurement tool depends on your specific needs and the environment in which you work. For instance, selecting a multimeter with advanced features like data logging can enhance diagnostic capabilities. Overall, if your work requires exact measurements, a multimeter’s digital display and durable build make it the tool of choice for dependable results.

Troubleshooting Industrial Equipment

Troubleshooting industrial equipment requires accurate measurements to quickly identify faults and minimize downtime. Using tools with wireless connectivity allows you to transmit data seamlessly to your digital interface, speeding up diagnostics. A multimeter with Bluetooth or Wi-Fi capabilities lets you monitor readings remotely, which is ideal for hard-to-reach or hazardous areas. Additionally, a clamp meter with a digital interface provides real-time updates on current flow, helping you pinpoint issues without interrupting equipment operation. This combination of wireless connectivity and digital interfaces enhances efficiency, reduces errors, and enables faster decision-making. By leveraging these advanced features, you guarantee thorough inspections while maintaining safety and minimizing equipment downtime. In industrial settings, these tools are indispensable for precise, efficient troubleshooting.

Testing Motor Windings and Coils

When testing motor windings and coils, accurate measurements are essential to guarantee the motor operates safely and efficiently. Motor winding testing helps identify issues like shorts or opens in the coils, preventing potential failures. To perform this, you’ll measure coil resistance using a multimeter set to the appropriate ohmmeter range. A low, consistent resistance indicates healthy windings, while significant deviations suggest damage or short circuits. Clamp meters are less effective for direct coil resistance measurement but excel at non-contact current readings during motor operation. Always ensure the motor is disconnected from power before testing to avoid false readings and safety hazards. Proper coil resistance measurement provides reliable data, helping you catch issues early and maintain peak motor performance. Incorporating holistic SEO strategies can also improve your understanding of electrical components and testing procedures, making your maintenance more effective. Additionally, understanding the fundamentals of electrical testing can help you interpret readings more accurately and troubleshoot problems more efficiently.

Monitoring Electrical Panels and Distribution Boards

Monitoring electrical panels and distribution boards is essential for ensuring the safety and efficiency of your electrical system. Using a clamp meter or multimeter with wireless testing capabilities allows you to check current flow without opening panels, reducing risk. A digital display helps you quickly read measurements, making troubleshooting faster and more accurate. When monitoring, consider the following:

| Tool Type | Advantage |

|---|---|

| Clamp Meter | Non-intrusive, easy wireless testing |

| Multimeter | Precise voltage and resistance readings |

A clamp meter excels for quick, on-the-spot current checks, especially when working in tight spaces. Additionally, choosing the right tool can enhance your safety protocols during electrical inspections. Meanwhile, a multimeter offers detailed diagnostics for voltage and resistance. Both tools are indispensable for maintaining safe, efficient electrical panels. Digital display features also assist in minimizing errors during testing, which is vital for accurate readings. Understanding angel number soulmate signs can help identify optimal times for electrical work, ensuring harmony and safety during maintenance.

Conducting Quick, On-the-Go Checks

Conducting quick, on-the-go checks allows you to efficiently assess electrical conditions without interrupting system operation. Using a handheld device with a digital display, you can instantly read voltage, current, or resistance levels, enabling swift troubleshooting. Clamp meters excel here because they let you measure current without disconnecting wires—simply clamp around a conductor and get an immediate reading. Multimeters, on the other hand, are useful for more detailed diagnostics but require direct contact with the circuit, which can be less convenient for quick checks. With a digital display, you get clear, accurate readings at a glance, making it easier to identify issues promptly. This portability and ease of use make handheld clamp meters and multimeters essential tools for on-the-go assessments.

Frequently Asked Questions

Can a Clamp Meter Measure DC Currents Accurately?

A clamp meter can’t measure DC currents accurately because it relies on detecting magnetic fields, which are only present in AC currents. DC currents don’t generate changing magnetic fields, making it difficult for the clamp meter to provide precise readings. For circuit protection and accuracy with DC, you should use a multimeter. This guarantees you get reliable measurements without risking damage to your equipment or overlooking critical circuit issues.

Are Multimeters Suitable for High-Voltage Electrical Testing?

Like a seasoned sailor steering stormy seas, you can rely on multimeters for high-voltage testing, but only if they’re rated for such tasks. They excel in voltage measurement, making them suitable for high-voltage electrical testing when equipped with the proper safety ratings. Always double-check the device’s specifications before tackling high-voltage environments; otherwise, you’re risking more than just a faulty reading. Safety first ensures smooth sailing.

How Do Clamp Meters Perform in Low-Current Measurement Scenarios?

In low-current measurement scenarios, clamp meters excel because they allow you to measure current without breaking the circuit, providing convenience and safety. However, they may have limitations in low-current accuracy compared to traditional multimeters. If you’re working with very small currents, a multimeter might deliver more precise readings. Use a clamp meter for quick, non-intrusive measurements, but rely on a multimeter when high accuracy in low-current readings is essential.

Is There a Risk of Damage When Using a Clamp Meter on Live Circuits?

Using a clamp meter on live circuits generally poses minimal risk if you follow proper circuit safety procedures. Make certain the device is compatible with the circuit’s voltage and current levels to prevent damage. Always keep your hands clear of live parts and use the meter’s proper settings. When used correctly, clamp meters are safe and efficient for measuring current without directly contacting live wires, reducing the risk of electrical hazards.

Can Multimeters Detect Magnetic Fields or Only Electrical Parameters?

A penny saved is a penny earned, so knowing your tools matters. Multimeters primarily measure electrical parameters like voltage, current, and resistance, but they don’t detect magnetic fields or perform magnetic detection. For field measurement related to magnetic fields, you need a specialized device like a gaussmeter or a clamp meter with magnetic sensing capabilities. Use the right tool to get accurate magnetic field readings and avoid unnecessary errors.

Conclusion

Choosing between a clamp meter and a multimeter depends on your specific electrical tasks. Did you know that about 70% of electricians prefer clamp meters for quick current measurements because they reduce downtime and improve safety? Whether you’re diagnosing faults or testing motors, understanding each tool’s strengths guarantees safer, more efficient work. Keep the right tool handy, and you’ll handle electrical challenges confidently and accurately every time.