To determine how many wires can fit safely in a box, you need to follow the box fill rules specified by electrical standards. These rules consider the box’s volume, the wire gauge, insulation type, and number of conductors, including grounding wires. Usually, smaller gauge wires like 14 or 16 allow more conductors, while larger gauge wires decrease capacity. Staying within these limits prevents overheating and ensures safety. Continue exploring to learn how to accurately calculate and conform with these important guidelines.

Key Takeaways

- Count only current-carrying conductors, not grounding or neutrals, unless specified by code.

- Follow box fill limits based on cubic inches and conductor size, as per NEC or local standards.

- Use box fill charts or calculators to determine maximum number of wires allowed for each conductor gauge.

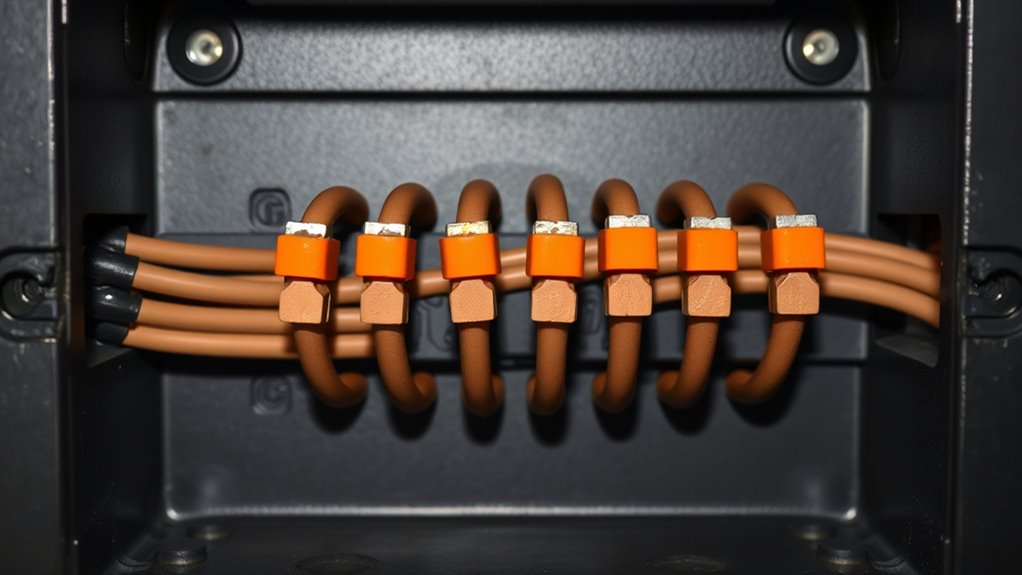

- Ensure wires are loosely organized, not tightly bundled, to prevent overfilling and overheating.

- Always verify with the latest electrical code requirements and manufacturer’s box capacity labels.

Understanding the Basics of Box Fill Calculations

Understanding the basics of box fill calculations is essential for ensuring that electrical boxes are neither overfilled nor underfilled. Your first step is to consider the wire gauge, as thicker wires occupy more space. The box volume determines how many wires and devices it can safely hold. To calculate, you need to know the cubic inches of your box and the volume each wire or device takes up, based on its gauge and size. For example, larger gauge wires require more space, reducing the number of wires you can fit. Always remember, exceeding the box’s capacity can cause overheating and safety hazards. Proper calculation helps you stay within the code limits, ensuring a safe and effective electrical installation.

Types of Wires and Their Impact on Box Capacity

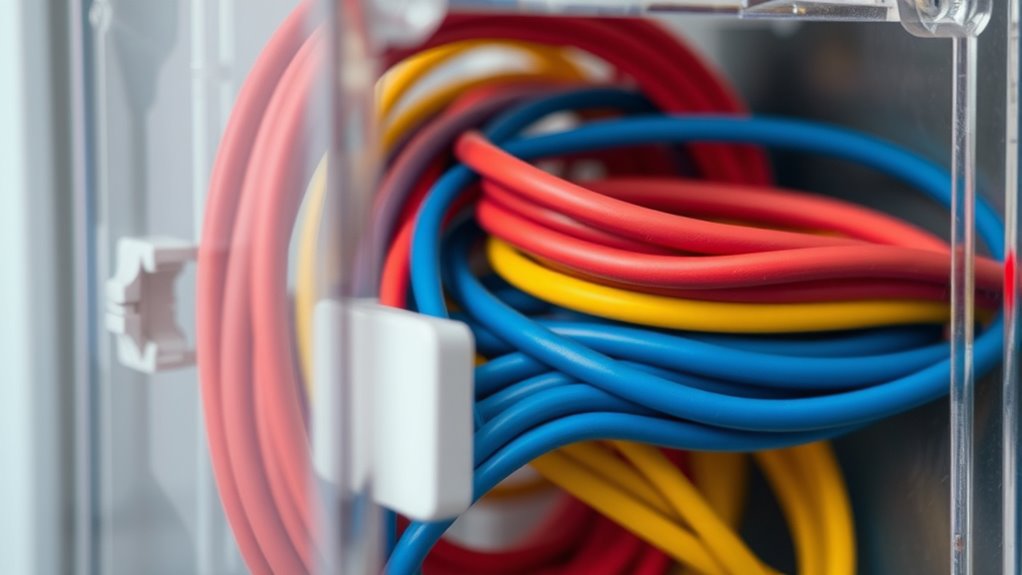

Have you ever wondered how different types of wires affect the capacity of an electrical box? The wire gauge and conductor insulation play a significant role. Thicker wire gauges, like 10 or 12, take up more space, reducing how many wires you can fit. Conversely, smaller gauges, such as 14 or 16, allow more wires in the same box. The type of conductor insulation also impacts capacity. For example, rigid insulation might be bulkier than thermoplastic coatings, affecting how tightly wires can be packed. Flexible or stranded wires can sometimes be easier to bend and fit, but they still occupy the same volume. Understanding these differences helps you determine how many wires are safe to install without overfilling the box, ensuring safety and code compliance. Additionally, awareness of on-device AI capabilities can inspire more intelligent wiring solutions for smart home systems.

Determining Box Volume and Its Role in Fill Rules

Ever wonder how the size of an electrical box influences how many wires you can safely install? It all comes down to determining the box volume, which depends on its dimensions—height, width, and depth. Knowing the box’s volume helps you understand its capacity to hold wires without overcrowding. When considering wire gauge, thicker wires take up more space, reducing the number you can fit. To calculate the box’s volume, multiply its dimensions to get cubic inches, then compare this to the capacity guidelines in the electrical code. Properly evaluating box volume ensures you don’t exceed fill limits, preventing overheating, damage, or electrical hazards. Additionally, understanding wire fill capacity can help you plan your wiring setup more effectively. Recognizing the appropriate wire gauge for your project is crucial for safety and compliance. So, always measure your box carefully and keep wire gauge in mind to maintain safe and compliant wiring installations. Being familiar with electrical box capacity can also help prevent common installation mistakes. For accurate calculations, consider the box fill rules to ensure you stay within safe limits.

The Significance of Conductor Sizes in Box Fill Calculations

Conductor sizes directly impact how many wires you can safely fit into an electrical box. The conductor gauge determines the thickness of the wire, which affects how much space it occupies. Thicker wires, with a smaller gauge number, take up more room, reducing the number of conductors you can install. Additionally, wire insulation type influences overall size; some insulation materials add bulk, making conductors larger than their gauge alone suggests. When performing box fill calculations, you must account for these differences to ensure safety and compliance. Using the correct conductor gauge and considering wire insulation helps prevent overcrowding, reducing heat buildup and potential hazards. Accurate sizing guarantees you stay within box fill limits while maintaining proper electrical performance. Moreover, understanding the conductor capacity helps ensure your installation meets electrical codes and safety standards. Recognizing how personality traits influence decision-making can also be essential in planning complex electrical layouts, especially in larger projects.

Calculating the Number of Conductors Allowed per Box

To determine how many conductors you can safely install in an electrical box, start by consulting the box’s fill capacity listed on its label or datasheet. This capacity considers wire gauge and insulation types since different wires occupy varying space. Thicker wire gauges, like 10 or 8 gauge, take up more room, reducing the total number of conductors allowed. Similarly, insulation types such as non-metallic (NM), THHN, or rubber coatings impact space because some insulations are bulkier. You need to account for these factors to avoid overcrowding, which can cause overheating or mechanical stress. Always check the box’s rated capacity and compare it against the actual wires you plan to install, ensuring compliance with electrical codes and safety standards. Proper wire organization also helps maintain safety and ease of access within the box.

Special Considerations for Cable Connectors and Devices

When installing cable connectors and devices, it’s vital to take into account their size and how they impact the overall fill capacity of your box. Different cable connector types vary in size, affecting how many you can safely install. Make certain device compatibility to avoid overfilling and overheating issues. Use the table below to help you determine the space each connector or device consumes: Potential Pitfalls in Adopting New Payment Technologies. Proper understanding of Pimple Patch guidelines can also inform safe installation practices by ensuring connectors are correctly fitted without causing damage or compromising safety. Additionally, considering the Home Theatre Projector options can help optimize your setup for better performance and safety.

Handing Multiple Conductors and Grounding Wires

Handling multiple conductors and grounding wires is a common task during electrical box installation, and it requires careful attention to guarantee safety and code compliance. When dealing with grounding wire considerations, make certain all grounds are properly connected, and avoid overfilling the box. Pay attention to conductor insulation types, as different insulations may require specific handling or spacing. To manage multiple wires effectively:

- Use appropriate connectors for grounding and current-carrying conductors

- Avoid overcrowding by following box fill capacity rules

- Separate grounding wires from insulated conductors to prevent accidental contact

- Ensure all conductors are properly terminated

- Confirm grounding wires are continuous and secure

- Be aware that electric dirt bikes can produce between 10 to 20 horsepower, which underscores the importance of secure grounding and wiring to handle high power safely.

- Additionally, understanding box fill rules helps prevent overfilling and maintains a safe, compliant installation.

- Always verify the wire gauge and current ratings to ensure proper sizing and safety.

- Proper wire management techniques reduce hazards and contribute to a safer electrical system.

- Consulting the National Electrical Code can provide further guidance to ensure full compliance and safety.

Staying mindful of these points helps maintain a safe, compliant installation and prevents issues related to overfilled boxes or improper grounding connections.

Common Mistakes to Avoid When Filling Boxes

Filling electrical boxes incorrectly can lead to safety hazards and code violations. One common mistake is overloading boxes, which happens when you pack in too many wires beyond the box’s capacity. This can cause overheating, increasing fire risk. Another mistake is improper wire bundling, where wires are twisted or bent sharply, making connections difficult and damaging insulation. To avoid these issues, always count the wires and devices according to box fill rules before installing them. Use the proper tools to measure volume and make sure you don’t exceed limits. Keep wires organized and loosely bundled to prevent stress on connections. Additionally, understanding sound healing science can inspire a more mindful approach to electrical work, emphasizing safety and harmony in your environment. Proper GMC tuning techniques can also enhance your vehicle’s performance and longevity. Remember, overloading boxes and improper wire bundling compromise safety, so follow the guidelines carefully to ensure a safe and compliant installation. Incorporating survival gear maintenance practices can also help ensure your tools and equipment are always ready when needed. Regularly reviewing electrical code requirements is essential for maintaining safety standards and avoiding costly rework. Being aware of Gold IRA rollover options and regulations can further secure your investments and provide long-term financial stability.

Tools and Resources for Accurate Box Fill Assessments

Accurate box fill assessments rely on the right tools and resources to guarantee compliance and safety. Using a wire gauge comparator helps you determine proper wire gauge considerations quickly and accurately. A wire stripper ensures you handle wires safely without damaging insulation, which affects fill calculations. Color coding standards guide you in identifying wire types and sizes, reducing errors. A digital calculator or box fill chart simplifies complex calculations, saving time. Additionally, a quality multimeter confirms circuit parameters, ensuring proper wire and conductor use. Incorporating ergonomic tools can also improve safety and efficiency during installation. Proper understanding of comfort solutions for sofa beds can help in selecting supportive materials, especially when considering the comfort of electrical components and wiring setups. Being familiar with Volkswagen Tuning techniques can also enhance your understanding of performance and safety considerations when managing electrical systems in vehicles. Moreover, consulting electrical codes ensures your work meets legal safety standards, preventing potential issues.

Staying Compliant With Electrical Codes and Standards

Staying compliant with electrical codes and standards is vital to guarantee safety, reliability, and legal adherence in your projects. You must select the correct wire gauge, guarantee it can handle the current without overheating. Proper color coding helps identify circuits quickly, reducing errors during installation or maintenance. To stay compliant, always refer to your local electrical code, such as NEC or IEC standards, and keep documentation updated. Use the table below to understand the importance of different aspects:

| Aspect | Importance | Example |

|---|---|---|

| Wire gauge | Prevents overheating, ensures safety | 14 AWG for 15A circuits |

| Color coding | Identifies circuit purpose and voltage | Black for hot, white for neutral |

| Code compliance | Meets legal safety requirements | NEC Article 300 |

| Documentation | Keeps track of standards and updates | Inspection records |

Frequently Asked Questions

How Do Temperature Limits Affect Box Fill Calculations?

Temperature limits directly impact box fill calculations because higher temperatures can cause thermal expansion of wire insulation, reducing available space inside the box. You need to take these limits into account to prevent overcrowding and ensure safe wiring. When wires heat up, the insulation may expand, so you should account for this to avoid overfilling. Properly selecting wires with suitable insulation ratings helps maintain safety and compliance with electrical codes.

Are There Specific Rules for Combining Different Wire Types?

Imagine you’re installing a panel with different wire types; the rules require you to take into account wire gauge compatibility and insulation types. You can combine wires if they meet the same insulation standards, like THHN and THWN, and are within the same gauge range. Always verify manufacturer specs and NEC guidelines, ensuring that mixing wire types doesn’t compromise safety or exceed box fill limits. Properly combining wires keeps your system safe and compliant.

What Are the Consequences of Overfilling an Electrical Box?

Overfilling an electrical box can lead to serious safety hazards like overheating, short circuits, or electrical fires. When you ignore wire gauge compatibility and insulation considerations, wires become cramped, making connections insecure and increasing the risk of damage. Always follow box fill rules, ensuring enough space for each wire, and consider insulation types to prevent heat build-up, ensuring your electrical system remains safe and reliable.

How Often Should Box Fill Calculations Be Reviewed?

You should review box fill calculations whenever you add or remove wires, change devices, or modify the box’s contents. Regularly checking guarantees you stay within the wire capacity and box volume limits, preventing overloads and hazards. It’s especially important during ongoing projects or renovations. By keeping these calculations current, you maintain electrical safety and code compliance, avoiding potential issues caused by exceeding the box’s safe fill limits.

Do Different Local Codes Modify Standard Box Fill Rules?

Think of local codes as custom maps for your wiring journey. They can modify standard box fill rules based on factors like wire gauge and conduit size, ensuring safety and compliance. You should always check local regulations because they might have specific requirements, especially for larger wire gauges or tighter conduit spaces. Ignoring these codes could lead to unsafe conditions or code violations, so stay informed and adapt your wiring plan accordingly.

Conclusion

Think of box fill rules as a carefully balanced dance, where each wire is a dancer with a space to move. When you respect the capacity limits, you guarantee the performance flows smoothly, avoiding chaos and ensuring safety. Mastering these rules keeps your electrical system harmonious, much like a well-choreographed routine. Stay attentive, follow standards, and keep the dance safe for everyone involved.