To guarantee reliable connections with pigtails, you should follow proper installation standards, select quality materials suited for your environment, and use the right tools for clean cleaves and secure terminations. Regular inspections, cleaning, and testing help prevent issues before they arise. Proper shielding, sealing, and handling also extend your pigtails’ lifespan. Want to know proven techniques to get it just right? Keep exploring for expert tips on long-lasting, dependable links.

Key Takeaways

- Follow proper installation standards, including thorough cleaning and precise alignment during splicing and termination.

- Use high-quality materials and environmental protections like weatherproof enclosures and appropriate coatings.

- Employ the right tools, such as fiber cleavers and polishing equipment, for consistent, low-loss connections.

- Conduct regular visual inspections and testing to identify and address damage or contamination early.

- Ensure complete shielding coverage and proper cable management to prevent environmental damage and signal interference.

Understanding the Importance of Proper Pigtail Preparation

Proper pigtail preparation is essential to guarantee reliable electrical connections. Ensuring fiber optic cleanliness is crucial; dust, dirt, or oil on connectors can lead to signal loss or intermittent connections. Always inspect and clean connectors thoroughly before splicing or connecting to equipment. Compatibility is equally important—using compatible connectors reduces insertion loss and prevents damage. Mismatched connectors can cause poor contact, affecting overall performance. Take the time to check that your pigtails match the system specifications and connector types. Proper preparation minimizes errors and saves time during installation or maintenance. When you prioritize fiber optic cleanliness and connector compatibility, you set a solid foundation for a stable, high-quality connection that lasts. Additionally, understanding the importance of color accuracy and proper contrast ratios can help ensure your projectors deliver optimal image quality, making your home theater experience truly immersive. This careful approach is key to avoiding costly repairs and ensuring top-notch performance.

Selecting the Right Materials and Components for Your Pigtails

Choosing the right materials and components for your pigtails is crucial to guarantee peak performance and durability. Selecting appropriate fiber optic coatings ensures maximum protection against environmental damage and minimizes signal loss. Additionally, understanding electrical connector types is essential to match your application’s needs, whether you’re using LC, SC, or ST connectors. Use quality components to prevent connection failures and ensure long-term reliability. Consider the compatibility of fiber optic coatings with your environment and the electrical connector types that suit your system. Proper material selection can help prevent issues caused by environmental factors and improve overall system stability. For example, selecting coatings with UV-resistant properties is vital for outdoor installations exposed to sunlight. It’s also important to evaluate chemical resistance to safeguard against corrosive elements in certain environments. Proper environmental considerations are key to choosing the most suitable components for your specific setting. Here’s a quick comparison:

| Fiber Optic Coatings | Connector Types |

|---|---|

| UV-resistant | LC, SC, ST |

| Fluoropolymer | FC, MU |

| Silicone | MTP/MPO |

| Polyimide | Custom or specialized |

| Acrylate | General-purpose |

Selecting the right materials guarantees solid, lasting connections. Properly matching these components based on environmental conditions can significantly extend the lifespan of your pigtails.

Essential Tools and Equipment for Pigtail Assembly

To guarantee your pigtail assembly performs reliably, having the right tools and equipment on hand is a must. Essential tools include:

- Fiber optic connectors: Ensure you have the correct connectors suited for your fiber type to guarantee a secure, low-loss connection.

- Crimping tool: Use a high-quality electrical crimping tool for attaching connectors securely, reducing the risk of connection failures.

- Fiber stripper and cleaver: These are vital for preparing fiber ends properly, ensuring minimal signal loss during splicing.

Having these tools ready makes the assembly process smoother and guarantees crucial performance. Proper handling of fiber optic connectors and precise electrical crimping are essential for a durable, reliable pigtail connection. Investing in quality equipment now saves time and reduces troubleshooting later.

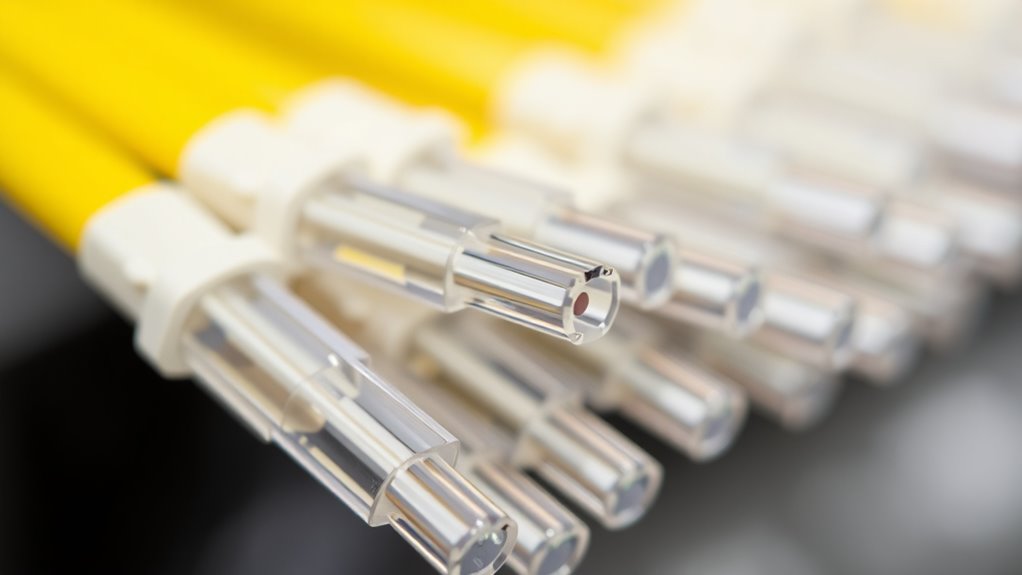

Techniques for Cleaving and Polishing Fiber Optic Pigtails

Achieving low-loss, high-quality splices starts with mastering the techniques for cleaving and polishing fiber optic pigtails. Proper fiber preparation ensures minimal signal loss and reliable connections. When cleaving, use a high-quality cleaver to create a clean, flat end face, avoiding micro-cracks. Polishing techniques are equally critical; they smooth the fiber end, reducing insertion loss. Use appropriate polishing films and pads, progressing from coarse to fine grit. Here’s a quick guide:

| Step | Action | Tips |

|---|---|---|

| 1 | Cleaving | Use a proper cleaver, apply even pressure |

| 2 | Coarse polishing | Remove surface irregularities |

| 3 | Fine polishing | Achieve a mirror finish |

| 4 | Inspection | Check for scratches or defects |

Consistent fiber preparation guarantees excellent performance of your pigtails. Incorporating advanced AI security technologies can further enhance the overall reliability of your fiber optic systems by monitoring and analyzing performance data to prevent potential issues before they occur. Additionally, maintaining proper environmental conditions during fiber termination can significantly improve the longevity and performance of your connections, especially when cleanliness is carefully managed throughout the process. Regularly monitoring connection quality and adhering to best practices can also help sustain optimal system performance over time.

Proper Splicing Methods for Electrical and Fiber Optic Pigtails

Once fiber ends are properly cleaved and polished, the next step is to splice them correctly to guarantee reliable connections. Proper splicing ensures minimal signal loss and durability. First, consider the connector types you’re working with, such as SC, LC, or ST, as each requires specific splicing techniques. Second, focus on precise alignment; use fusion splicing for fiber optics and mechanical splicing for electrical cables. Third, manage your cable well by employing proper cable management practices, like securing pigtails neatly to prevent stress. This not only preserves signal integrity but also simplifies future maintenance. Remember, the quality of your splice directly impacts connection reliability, so follow manufacturer instructions carefully and double-check your work before finalizing. Additionally, maintaining proper environmental conditions during splicing can significantly improve the overall quality and longevity of the connection. Proper technique selection is crucial for ensuring a durable and high-quality splice, especially in challenging environments. Incorporating specialized tools designed for fiber optic splicing can further enhance the accuracy and reliability of your work. Ensuring your equipment is well-maintained and calibrated can also prevent issues like air leaks that compromise connection quality. Moreover, understanding the importance of quality materials can make a significant difference in achieving lasting, dependable splices.

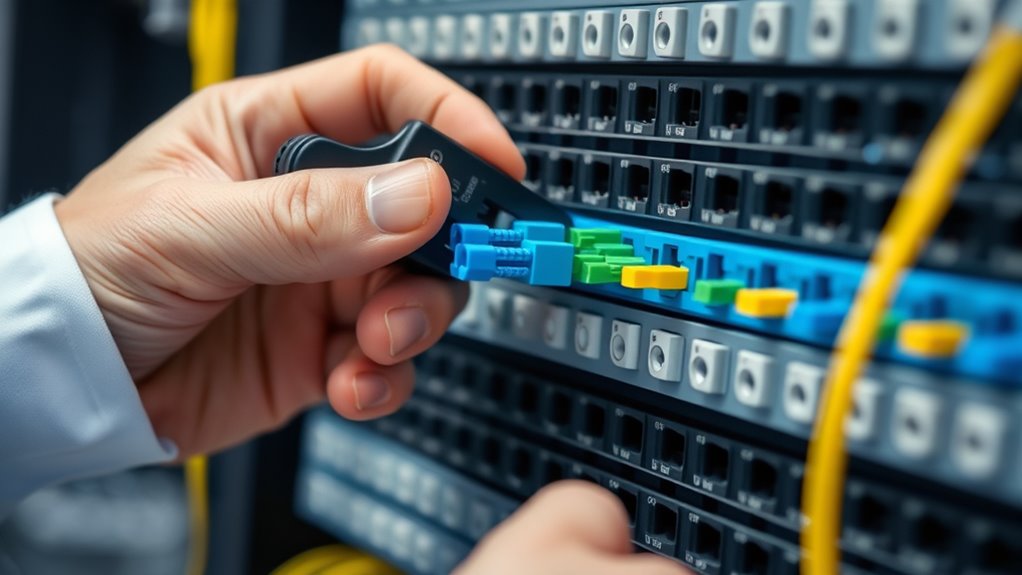

Ensuring Strong and Secure Terminations

Ensuring strong and secure terminations is essential for maintaining ideal signal quality and connection longevity. Selecting the right connector types is vital, as different applications demand specific options like LC, SC, or ST connectors. Proper installation standards must be followed to prevent signal loss and mechanical failure. Make sure connectors are properly cleaned, aligned, and firmly seated to avoid future issues. Use the appropriate tools and techniques to secure connections without damaging delicate fibers or wires. Inspect each termination for consistency and stability, ensuring there are no gaps or loose fittings. Adhering to established standards guarantees that your pigtails deliver reliable performance, whether in networking, telecommunications, or other critical systems. Proper handling of connectors is crucial to avoid damage and ensure longevity. Additionally, understanding connector standards helps in choosing compatible components and maintaining system integrity. Strong, well-executed terminations lay the foundation for a durable, high-quality connection.

Managing and Protecting Your Pigtails From Environmental Factors

Proper management and protection of your pigtails are essential to prevent damage caused by environmental factors. By focusing on effective cable management and pigtail customization, you can shield your connections from hazards like moisture, dust, and temperature extremes. To do this, consider these steps:

- Use cable ties or sleeves to organize and secure pigtails, reducing strain and movement. Additionally, selecting high-quality protective materials can enhance durability against harsh conditions.

- Apply weatherproof enclosures or protective boots to guard against moisture and dirt.

- Select pigtail materials suited for your environment, customizing lengths and connectors for ideal protection.

- Incorporate mindfulness techniques to remain attentive to signs of wear or damage, ensuring proactive maintenance. Being aware of environmental resilience helps in choosing the right protective measures for your pigtails.

- Regularly inspect and test your pigtails to identify potential issues before they lead to failure, supporting ongoing system reliability.

Implementing these strategies ensures your pigtails remain reliable and durable, even in challenging conditions. Properly managed and protected pigtails minimize maintenance and downtime, guaranteeing consistent performance over time.

Testing and Quality Assurance for Pigtail Connections

To guarantee your pigtail connections are dependable, you need to perform thorough testing and quality checks. Using visual inspection techniques, you can identify obvious defects, while continuity testing confirms proper electrical connections. Additionally, environmental durability checks help verify that your pigtails will withstand harsh conditions over time. Ensuring product authenticity is also crucial to confirm that your connections are made with genuine, high-quality components. Moreover, understanding the family background of the components can provide insights into their reliability and performance. Incorporating testing standards can further ensure that your processes meet industry benchmarks for safety and quality. Recognizing the emotional significance of reliable connections can also motivate rigorous quality assurance practices, as consistent performance is key to trust and safety. Staying informed about regional resources and tools can also enhance your ability to access the best testing equipment and expertise.

Visual Inspection Techniques

Visual inspection is a essential step in verifying the quality and reliability of pigtail connections. It helps you catch issues early, ensuring peak performance. First, examine the fiber optic connectors for cleanliness, scratches, or damage that could impair signal transmission. Second, check that the connectors are properly seated and aligned, preventing misconnection. Third, inspect insulation resistance, ensuring there are no exposed or damaged insulation that could cause signal loss or short circuits. Use a magnifying glass if needed to spot tiny cracks or debris. Maintaining strict visual inspection routines guarantees your pigtail connections meet quality standards. This process minimizes future failures by addressing problems before they escalate, ensuring your network remains reliable and performs at its best.

Continuity Testing Methods

Continuity testing is a essential step in verifying the integrity of pigtail connections, ensuring that the fiber optic path is complete and free of breaks. This process confirms that fiber optic splicing was successful and that no faults exist in the connection. Using a visual fault locator or an optical power meter, you can check for continuity by sending light through the fiber and confirming its arrival at the other end. For electrical continuity, a multimeter helps verify that the conductors within the pigtail are properly connected and conductive. These tests help catch issues like breaks, poor splices, or miswiring early, preventing future failures. Reliable continuity testing guarantees your pigtail connections are solid, reducing downtime and ensuring ideal performance in your fiber optic network.

Environmental Durability Checks

Environmental durability checks are essential for ensuring that pigtail connections withstand various conditions over time. These tests help confirm the connection’s resilience against factors like thermal expansion and chemical exposure. To do this effectively, you should focus on three key areas:

- Thermal Cycling Tests: Simulate temperature fluctuations to assess how thermal expansion affects the connection’s integrity.

- Chemical Resistance Tests: Expose pigtails to chemicals, oils, and moisture to ensure they resist corrosion and degradation.

- Environmental Stress Screening: Subject the pigtails to humidity, UV rays, and other environmental factors to verify long-term durability.

Performing these checks guarantees your pigtail connections remain reliable, even in harsh conditions. Proper testing ensures safety, longevity, and consistent performance over time.

Common Mistakes to Avoid During Pigtail Installation

Avoid common pitfalls like improper stripping techniques, which can damage the fiber and weaken the connection. Make certain you provide sufficient shielding coverage to prevent interference and signal loss. Rushing the termination process often leads to poor connections, so take your time to ensure each step is done correctly.

Improper Stripping Techniques

When installing pigtails, improper stripping techniques can lead to connectivity issues and compromised connections. Incorrect stripping can damage fibers or leave too much protective coating, causing signal loss. To avoid these mistakes, keep in mind:

- Do not strip too deep or too shallow; both can damage fibers or leave connectors exposed.

- Use the right tools designed for fiber optic cables to ensure clean cuts.

- Avoid pulling or twisting the fiber during stripping, which can cause micro-cracks and weaken the connection.

Insufficient Shielding Coverage

Insufficient shielding coverage is a common mistake that can compromise the integrity of your pigtail connection. When shielding isn’t properly covered, it leaves your system vulnerable to interference, which can cause grounding issues and signal loss. Make sure the shielding extends fully to the connector, ensuring it’s compatible with your cable type. Overlooking this can lead to poor grounding, resulting in noise and unreliable data transmission. Additionally, incompatible connectors may not make proper contact with the shield, further weakening the connection. Always verify that your connectors are designed to match your shielding type and coverage requirements. Proper shielding coverage not only protects against external interference but also helps maintain a stable, reliable connection over time. Avoid shortcuts—proper coverage is essential for ideal performance.

Rushing Termination Process

Rushing the termination process during pigtail installation can lead to poor connections and long-term reliability issues. When you hurry, you risk neglecting fiber optic cleanliness, which is vital for maximum signal transmission. Additionally, rushing can cause improper sealing, increasing the chance of corrosion. To avoid these mistakes, focus on these key steps:

- Make certain fiber ends are thoroughly cleaned with appropriate cleaning tools before termination.

- Take your time to carefully align and secure the pigtail, preventing any micro-bends or misalignments.

- Finish by sealing the connection properly to prevent moisture ingress and corrosion.

Maintenance and Troubleshooting for Long-Lasting Pigtail Connections

Regular maintenance and troubleshooting are essential to guarantee your pigtail connections remain reliable over time. Start by inspecting fiber optic splicing regularly to ensure there are no cracks, dirt, or misalignments that could disrupt signal quality. Clean connectors carefully with appropriate tools to prevent dirt buildup. For electrical wiring, check for loose or corroded connections that might cause intermittent issues or failures. Use a visual inspection to identify damaged or frayed fibers and damaged insulation. If you notice any issues, re-splice fibers properly or replace damaged components. Keep your workspace clean and avoid excessive bending or stress on the pigtails. Routine checks help catch problems early, ensuring your connections stay stable and long-lasting.

Frequently Asked Questions

How Long Do Properly Installed Pigtails Typically Last?

Properly installed pigtails usually last between 10 to 15 years, depending on installation quality and environmental conditions. If you guarantee the connector lifespan is maximized, you’ll minimize issues like corrosion or wear. Regular inspections can help identify any early signs of deterioration. High-quality installation techniques and materials considerably extend the lifespan, so investing in professional setup really pays off in the long run.

Can Pigtails Be Reused After Disconnection?

Did you know that around 60% of technicians reuse connectors to save time? You can reuse pigtails after disconnection if they’re still in good condition, but it’s not always recommended. Connector reuse can affect the pigtail lifespan, risking signal loss or failure. Always inspect for damage or corrosion before reconnecting. Reusing pigtails is possible, but for maximum reliability, replacing them ensures consistent, secure connections.

What Are Signs of a Failing Pigtail Connection?

You’ll notice signs of a failing pigtail connection through visual inspection, such as corrosion, rust, or discoloration around the connection point. If the connection appears loose or damaged, it could also be a warning sign. You should address these issues promptly to prevent further damage or electrical failure. Regularly checking for corrosion signs and ensuring the connection remains tight will keep your pigtails functioning reliably.

Are There Specific Storage Conditions for Unused Pigtails?

Yes, you should store unused pigtails properly to guarantee their longevity. Follow storage tips like keeping them in a cool, dry, and dust-free environment, away from direct sunlight and extreme temperatures. Use preservation methods such as sealing them in anti-static bags or containers to prevent damage and corrosion. Proper storage helps maintain their quality, ensuring reliable connections when you need to use them again.

How Do Environmental Factors Affect Pigtail Longevity?

Environmental factors like UV exposure and moisture intrusion can substantially impact your pigtail longevity. UV rays cause the protective coating to degrade, leading to brittle fibers and potential failures. Moisture intrusion fosters corrosion and weakens connections over time. To guarantee durability, you should shield pigtails from direct sunlight, store them in dry environments, and use proper sealing techniques. Regular inspections help detect early signs of damage, extending their reliable performance.

Conclusion

By mastering proper pigtail preparation and installation, you guarantee reliable, long-lasting connections. Did you know that poor splicing can cause up to 70% of network failures? Taking the time to select quality materials, use the right tools, and follow best practices can substantially reduce that risk. Stay vigilant in testing and maintenance, and you’ll keep your connections secure and efficient, avoiding costly downtime and ensuring ideal performance every time.