NM-B cables work best in indoor residential settings where flexibility, easy installation, and safety are priorities, especially for wiring walls and ceilings. MC cables shine in commercial or industrial environments with moisture, physical damage risks, or outdoor use, offering higher durability and fire resistance. Choosing the right cable depends on your environment and safety needs. To determine which type suits your project, explore the detailed considerations for each below.

Key Takeaways

- NM-B is ideal for indoor residential wiring due to its flexibility, ease of installation, and cost-effectiveness.

- MC cable excels in environments requiring high durability, fire resistance, and protection against moisture or physical damage.

- Use NM-B for concealed, dry indoor applications like walls and ceilings; choose MC for exposed or damp locations.

- MC cables are better suited for industrial or outdoor settings where environmental resistance and durability are priorities.

- Consider environmental conditions and safety requirements to determine when each cable type provides optimal performance.

Understanding the Construction and Materials of NM-B and MC Cables

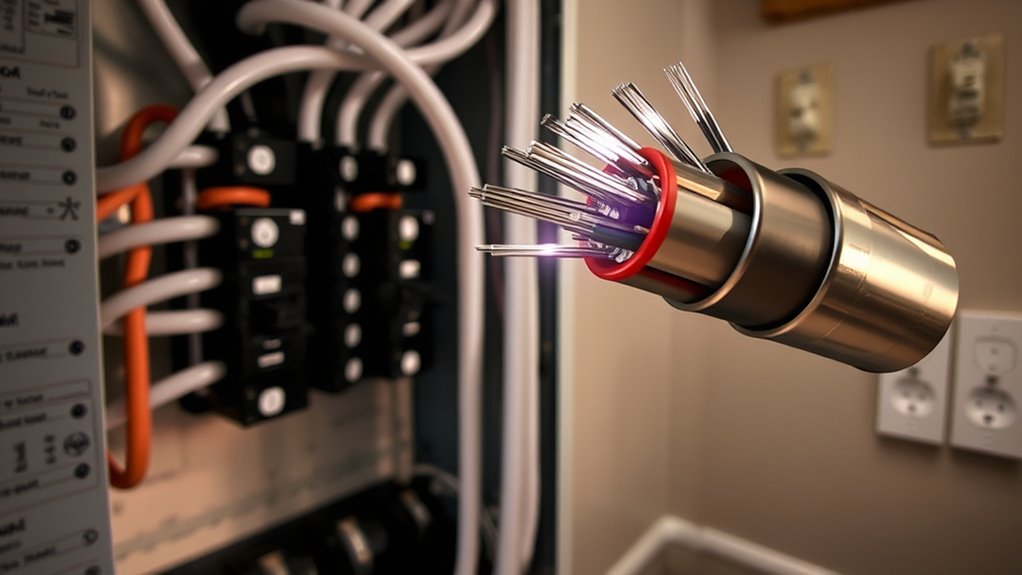

To understand the differences between NM-B and MC cables, it’s important to examine how they’re constructed and what materials are used. NM-B cables consist of insulated conductors, typically made of copper or aluminum, bundled together with a plastic sheathing. The insulation offers some fire resistance, but primarily focuses on safety and electrical conductivity. In contrast, MC cables feature a metal armor or flexible conduit around insulated conductors, providing enhanced fire resistance and physical protection. This metal layer also improves electrical conductivity and shields against interference. The materials used in MC cables make them more durable and suitable for demanding environments. Additionally, the fire resistance properties of MC cables are superior due to their metal armor, making them ideal for more hazardous or exposed settings. This increased durability and fire resistance contribute to their suitability for outdoor and industrial applications. The installation process for MC cables can be more complex due to their rigid or armored nature, but this complexity results in greater safety and longevity. Proper installation techniques, such as secure grounding and proper conduit connections, are essential to maximize their benefits. Overall, while NM-B prioritizes simplicity and flexibility, MC cables combine robust construction with superior fire resistance and electrical conductivity.

Typical Indoor Applications for NM-B Cable

NM-B cable is commonly used for indoor wiring in residential and commercial buildings because it’s flexible and easy to install. Its wire color coding simplifies identifying circuits, making troubleshooting straightforward. Typically, you’ll find black, red, and white conductors, with the insulation types designed for safe, reliable performance indoors. The cable’s insulation, usually made of PVC or other thermoplastic materials, provides protection against moisture, heat, and physical damage. NM-B is ideal for wiring outlets, switches, and lighting fixtures where a durable, code-compliant solution is needed. Its versatility and straightforward installation make it a go-to choice for general indoor wiring projects. Just guarantee the proper gauge and insulation type match your specific electrical requirements for safety and efficiency. Additionally, choosing the right insulation material ensures optimal performance and safety in various indoor environments. Proper planning and preparation and adherence to electrical codes are essential to ensure safe and compliant installations. Being aware of the specific application requirements helps in selecting the most suitable cable type for each project.

When to Use MC Cable for Commercial and Industrial Settings

When selecting wiring methods for commercial and industrial settings, MC cable is often the best choice due to its durability and fire-resistant properties. Its cable insulation provides added protection against environmental hazards, making it suitable for harsh conditions. You should consider MC cable when working in areas exposed to moisture, chemicals, or physical damage. The conductor materials, typically copper or aluminum, ensure reliable conductivity and long-term performance. MC cable’s sturdy construction and fire-resistant insulation make it ideal for demanding environments where safety and longevity are priorities. Use it for exposed runs, industrial equipment, or areas requiring flexible and robust wiring solutions. Overall, MC cable offers the durability and safety features necessary for high-demand commercial and industrial applications.

Code Compliance and Safety Considerations for Both Cables

Choosing the right wiring method involves understanding how each cable type complies with electrical codes and safety standards. Both NM-B and MC cables meet specific requirements, but their fire safety features differ. NM-B cables are generally suitable for indoor use where fire safety is a priority, and they conform to electrical code standards for residential wiring. MC cables, with their metal armor, provide enhanced protection against physical damage and fire hazards in commercial or industrial settings.

Additionally, fire safety features vary between the two types and are crucial to consider in relation to the specific application. It is also important to consider the installation environment, as certain conditions may favor one type of cable over the other for optimal safety and durability. Recognizing the fire safety standards that each cable adheres to can help ensure compliance and safety in different scenarios.

Understanding cable ratings and how they relate to the environment ensures that the selected wiring method maintains safety and performance over time.

Key considerations include:

- Ensuring cables are rated for the environment and application

- Verifying fire safety ratings meet local code requirements

- Confirming proper grounding and insulation

- Following manufacturer and electrical code guidelines for installation

This ensures safe, compliant wiring that minimizes fire risks.

Installation Flexibility: Comparing the Handling and Mounting of NM-B and MC

When installing NM-B or MC cable, you’ll notice differences in how easy they are to handle and mount. NM-B is lightweight and flexible, making it simple to work with in tight spaces. MC cable offers more mounting options, giving you versatility in how you secure it throughout your project. Additionally, MC cable’s robust materials provide increased durability for long-term installations. The ability to resist environmental factors further enhances its suitability for various settings. Moreover, understanding the weight differences is important to ensure proper handling and safety during installation. Because of its construction, MC cable can also be more forgiving in challenging installation environments, making it a preferred choice for complex or outdoor setups.

Ease of Handling

Both NM-B and MC cables are designed to be relatively easy to handle during installation, but their flexibility and mounting options can differ markedly. NM-B cables are lightweight and flexible, making them simple to route through tight spaces. They typically feature clear cable color coding, which helps identify circuits quickly, and have thinner insulation, reducing bulk. In contrast, MC cables are more rigid but offer better protection and durability, especially in challenging environments. When handling MC, you’ll notice their sturdiness can make routing slightly more cumbersome. Consider these points:

- NM-B’s flexibility simplifies bending around corners

- MC’s sturdiness provides more secure mounting options

- Cable color coding aids quick identification

- Insulation thickness impacts ease of manipulation

- Tuning considerations can influence cable selection based on the environment and handling requirements

These factors influence how easily you can handle and install each type.

Mounting Versatility

Mounting versatility is a key difference between NM-B and MC cables, affecting how easily they can be installed in various environments. NM-B cables are lightweight and flexible, making them simple to route through walls and ceilings, especially where aesthetic considerations matter. They’re ideal for hiding behind drywall or using wireless alternatives for low-profile setups. MC cables, on the other hand, feature a robust metal armor that’s more rigid but offers secure mounting in exposed or industrial areas. Their durable construction allows for direct attachment to surfaces without additional conduit. If you need a clean, discreet look, NM-B provides greater flexibility, but MC’s mounting options excel in more demanding environments where strength and protection are priorities. Additionally, installation methods play a crucial role in choosing the appropriate cable type for specific projects. Understanding cable durability can help determine the best option for long-term performance and safety. Considering fire resistance is also important, especially in settings where safety standards are strict. Proper mounting techniques can also influence the overall safety and compliance of the electrical system, making it essential to evaluate installation best practices for each cable type. Furthermore, selecting the right cable can impact overall cost efficiency and ease of future upgrades or repairs.

Cost Factors and Long-Term Durability of NM-B Vs MC Cable

Cost is a significant factor when choosing between NM-B and MC cable, as initial expenses can vary considerably. Your cost comparison should consider both upfront costs and long-term durability factors. NM-B cable typically costs less initially, making it appealing for smaller projects. However, MC cable might have higher upfront costs but offers better protection and longevity in demanding environments. Additionally, the evolving trends in construction and electrical needs, such as increased emphasis on safety standards, influence the suitability of each cable type. NM-B is easier to install, reducing labor costs. MC cable’s durable metal jacket resists damage over time. Long-term, MC cable often requires less maintenance. NM-B’s insulation may degrade faster in harsh conditions. Your decision should weigh these factors to ensure you get the best value for your investment, considering both immediate expenses and how well the cable performs over time.

Environmental Conditions Favoring One Cable Type Over the Other

When you’re working in moisture-rich environments, MC cables usually hold up better than NM-B because of their greater resistance to water. In high-temperature areas, NM-B cables might struggle with insulation breakdown, making MC a safer choice. Understanding these conditions helps you select the right cable for durability and safety. Additionally, considering cable insulation materials can further ensure optimal performance in specific environments, especially when selecting materials designed for extreme temperature resistance. For example, cables with fire-resistant insulation are essential in settings with high heat or risk of fire, enhancing safety and longevity.

Moisture-Rich Environments

In moisture-rich environments, choosing the right cable type becomes essential for safety and durability. MC cables are generally better suited here because their cable insulation is designed to resist moisture, preventing corrosion and short circuits. They also feature durable, sealed conduits that protect the conductor types inside from water exposure. NM-B cables, with their traditional insulation, are more vulnerable to moisture damage, risking degradation over time. When selecting cable insulation, consider the environment’s humidity levels and potential water contact. MC cables typically have a protective metal sheath, making them ideal for damp locations. Keep in mind that the conductor types used in MC cables are often rated for outdoor or wet conditions, ensuring long-term performance and safety in moisture-rich environments.

High-Temperature Areas

High-temperature areas present unique challenges for cable selection, as heat can compromise insulation and conductor integrity. In such environments, choosing fire resistant wiring becomes vital to prevent fires and ensure safety. MC cables often feature cable insulation types that withstand higher temperatures, making them suitable for these conditions. Their robust insulation materials resist degradation from heat, maintaining electrical performance and safety. NM-B cables, with standard insulation, may not perform well in high-temperature settings, risking insulation failure. For environments like industrial spaces or near heat sources, selecting cables with specialized insulation and fire resistant wiring is essential. This guarantees durability, reduces fire hazards, and complies with safety codes, making MC cables the better choice when high thermal resilience is required.

Future-Proofing Your Wiring: Choosing the Right Cable for Upgrades

Choosing the right cable now can save you headaches and costs down the line as your electrical needs evolve. When future-proofing your wiring, consider selecting cables with appropriate wire gauge to handle increased loads and versatile insulation types for various environments. Think about potential upgrades, like adding circuits or higher-power appliances.

Selecting the right cable now ensures reliable, adaptable wiring for future upgrades and increased electrical demands.

To guarantee your wiring stays reliable, look for:

- Thicker wire gauge for added capacity

- Insulation types suitable for moisture or heat exposure

- Compatibility with existing electrical systems

- Flexibility for easy upgrades or modifications

Frequently Asked Questions

How Do NM-B and MC Cables Differ in Fire Resistance?

You’ll find that NM-B cable offers limited fire resistance because its insulation, typically made of plastic, can burn easily. In contrast, MC cable has metal armor and fire-retardant insulation, making it better at resisting fire and preventing it from spreading. Because of its durable cable insulation, MC cable is preferable in areas where fire safety is a priority. Always choose the right cable based on fire resistance needs.

Can NM-B or MC Cables Be Used Outdoors Without Additional Protection?

You shouldn’t use NM-B or MC cables outdoors without proper protection. NM-B cable isn’t designed for outdoor durability or weather resistance, so exposure to moisture and UV rays can cause damage. MC cable offers better weather resistance and is more suitable for outdoor use, but still benefits from additional protection like conduit or weatherproof coverings. Always check local codes and manufacturer guidelines to guarantee safe outdoor installations.

What Are the Electrical Load Limits for NM-B Versus MC Cables?

You should check the insulation ratings for NM-B and MC cables to determine their load limits. NM-B cables generally have lower insulation ratings, making them suitable for lighter loads and dry, indoor environments. MC cables, with thicker, more durable insulation, handle higher electrical loads and are better for outdoor or exposed areas. Keep cost considerations in mind, as MC cables tend to be more expensive but offer greater protection and capacity.

How Do Installation Times Compare Between NM-B and MC Wiring?

You’ll find that NM-B cable often speeds up installation, taking about 20-30% less time than MC cable due to its flexibility and simpler setup. This increased installation efficiency can lower labor costs markedly, especially in large projects. While MC cable’s robustness might require more effort to install, NM-B’s lightweight design and ease of handling make it a favorite for quick, cost-effective wiring jobs.

Are There Any Specific Licensing Requirements for Installing MC Cable?

You need to check local licensing requirements before installing MC cable, as they often require licensed electricians. In many areas, you’ll need proper licensing and may also need installation permits to guarantee safety and code compliance. These regulations help verify that you’re qualified to handle the work correctly. Always consult your local building department or electrical authority to confirm specific licensing requirements and permit procedures for MC cable installations.

Conclusion

Choosing between NM-B and MC cable depends on your specific needs. NM-B is perfect for simple, indoor projects, while MC shines in demanding commercial and industrial environments. Consider safety, flexibility, and durability to avoid future headaches. Remember, picking the right cable can feel like finding a needle in a haystack — but making the right choice guarantees your wiring stands the test of time and environmental challenges like an unbreakable fortress.