Fusing each string is essential because it enhances its durability and strength, helping it withstand stress, tension, and wear over time. Proper fusing creates a sealed, reinforced tip that resists fraying, unwinding, and breakage, ensuring consistent performance. It also prevents issues like electrical shorts or tuning problems in musical strings, saving you time and effort on repairs. Mastering this step means longer-lasting, more reliable strings—stay with us to discover how to do it right.

Key Takeaways

- Proper fusing creates a sealed, reinforced tip that resists fraying and unwinding, extending string lifespan.

- Fusing enhances tension maintenance, ensuring strings stay tight and stable during use.

- It prevents damage, breakage, and wear, reducing the need for repairs or replacements over time.

- Well-fused strings improve safety by minimizing electrical shorts or failures in technical applications.

- Overall, fusing ensures durability, reliability, and consistent performance in various string-dependent projects.

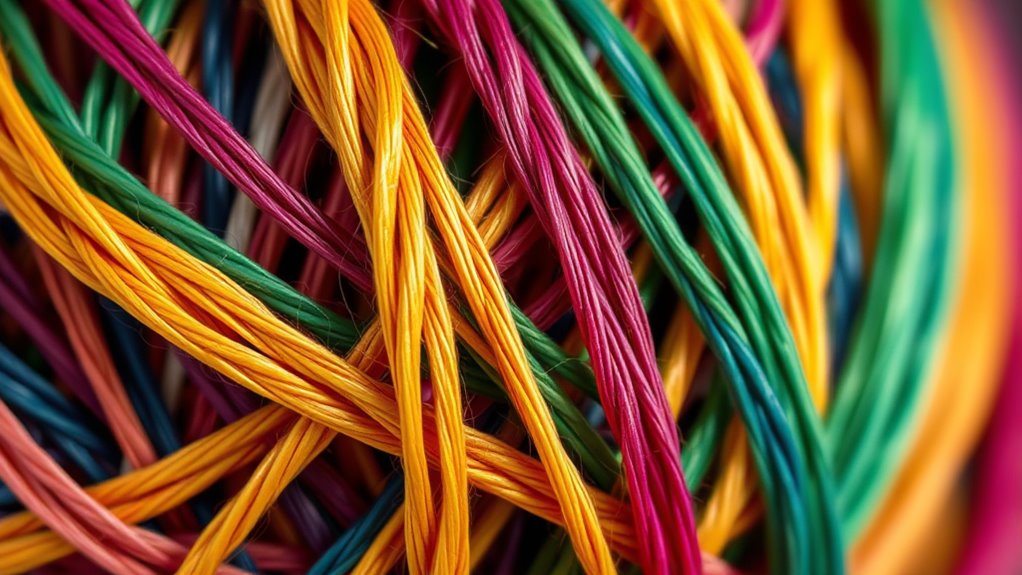

Fusing each string is a critical step in guaranteeing the durability and strength of your project, whether you’re working with electrical wires, musical instrument strings, or craft materials. When you take the time to properly fuse your strings, you markedly enhance their ability to withstand stress, tension, and everyday wear. This process helps prevent fraying, breakage, and loss of tension over time, which are common issues that can compromise the integrity of your work. Guaranteeing proper fusing means your strings will maintain their intended performance longer, saving you time and effort in repairs or replacements.

Proper fusing enhances string durability, ensuring long-lasting performance and preventing fraying or breakage over time.

String durability hinges on more than just the quality of the material; it depends heavily on how well you fuse the ends or connection points. Proper fusing creates a sealed, reinforced tip that resists fraying and unwinding, which are typical points of failure. When you fuse your strings effectively, you also improve tension maintenance. Tension is essential for many applications—whether you’re tuning a musical instrument or fixing an electrical connection—and it can be lost over time if the strings are not fused correctly. Well-fused strings stay tight and stable, maintaining their tension even after prolonged use, which guarantees consistent performance.

The process of fusing involves applying heat, adhesive, or a combination of both to the string ends. For electrical wires, this might mean soldering or crimping connectors securely. For musical strings, heat fusing or knotting techniques are used to prevent unraveling. When working with craft materials like embroidery or jewelry, heat sealing or glue can be employed to secure the ends. Each method requires precision; too much heat can weaken the string, while too little might not provide enough reinforcement. Your goal is to create a strong, lasting bond that supports the string’s intended function.

Fusing also contributes to safety and reliability, especially in electrical applications where loose or frayed wires pose risks. Properly fused strings reduce the chance of shorts or electrical failures. In musical contexts, they prevent the tension loss that can cause tuning issues or even breakage during performance. In crafting, they ensure your work remains intact over time, avoiding the frustration of unraveling or breakage. Additionally, understanding the importance of string tension can help you optimize your work for better performance and longevity.

Ultimately, fusing each string is a simple but essential step that impacts your project’s longevity and performance. By paying attention to string durability and tension maintenance, you’re taking proactive measures to guarantee your work remains strong, reliable, and efficient. Proper fusing not only protects your investment but also gives you peace of mind knowing that your strings are secure and durable in any application.

Frequently Asked Questions

How Does String Fusing Affect Overall Durability?

String fusing enhances overall durability by reinforcing the connection between strings, which helps them withstand higher string tension without breaking. When the fused strings are compatible in material, they bond better, reducing wear and tear over time. This process prevents slippage and distributes tension evenly, making your racket more resilient during intense play. Proper fusing ensures the strings stay intact longer, boosting your confidence and performance on the court.

Can Fusing Improve Sound Quality in Musical Instruments?

Fusing your strings acts like a master chef blending ingredients, enhancing the instrument’s voice. It can improve sound quality by reducing unwanted vibrations, allowing string resonance and tonal clarity to shine through. When strings are fused, they resonate more freely, producing richer, more focused tones. This process helps your instrument deliver clearer notes, making your performance more expressive and vibrant, like a symphony coming alive with every pluck and strum.

What Materials Are Best for Effective String Fusing?

You should choose materials with excellent compatibility, like certain plastics or metals, to guarantee effective string fusing. The key is to prioritize materials with strong adhesive strength, which helps create a durable bond. Avoid mismatched materials that might cause weak connections or deterioration over time. Using compatible materials with high adhesive strength guarantees a secure, lasting fuse, ultimately enhancing the instrument’s sound quality and reliability.

Is Fusing Necessary for All Types of Strings?

Like Da Vinci perfecting his art, you don’t need to fuse all types of strings, but it’s key for custom projects. Fusing helps with string customization, ensuring durability and a sleek look. It’s especially beneficial for aesthetic enhancement, giving your strings a polished, professional finish. So, while not always necessary, fusing can elevate your work, making your strings more reliable and visually appealing, just like a masterpiece.

How Does Temperature Impact the Fusing Process?

Temperature critically impacts the fusing process by affecting temperature effects on the fuse consistency. If you use too high a temperature, the fuse may become overly soft, leading to weak bonds or uneven fusion. Conversely, too low a temperature can result in insufficient fusing, causing weak connections. To achieve ideal fusing, you need to carefully control the temperature, ensuring the fuse consistency is just right for a strong, reliable bond.

Conclusion

So, next time you think fusing each string doesn’t matter, remember—it’s the tiny details that hold everything together. Ironically, neglecting this step might seem trivial, but it could unravel your entire project. You might be tempted to rush through, yet that small act of fusing could be the difference between success and failure. Turns out, in the world of strings, the tiniest fuse can make the biggest difference—proving that sometimes, the little things really do matter most.