Choosing between backstabs and screw terminals depends on your needs. Backstabs offer quick, easy wiring but may loosen over time, especially in vibrations. Screw terminals provide a more secure, durable connection suitable for long-term or heavy-duty projects. Consider factors like environmental conditions, cost, and safety to make the right choice. To verify you make the best decision, explore the key differences further as you continue.

Key Takeaways

- Screw terminals offer superior mechanical stability and resistance to vibration, making them ideal for long-term, heavy-duty applications.

- Backstabs provide quick, tool-free installation, suitable for DIY projects and environments prioritizing ease of setup.

- High-quality screw terminals generally have better corrosion resistance and durability over time compared to backstabs.

- Backstabs are more cost-effective initially but may require more maintenance and risk connection failure in demanding conditions.

- For safety and reliability in professional or vibration-prone setups, screw terminals are the safer and more durable choice.

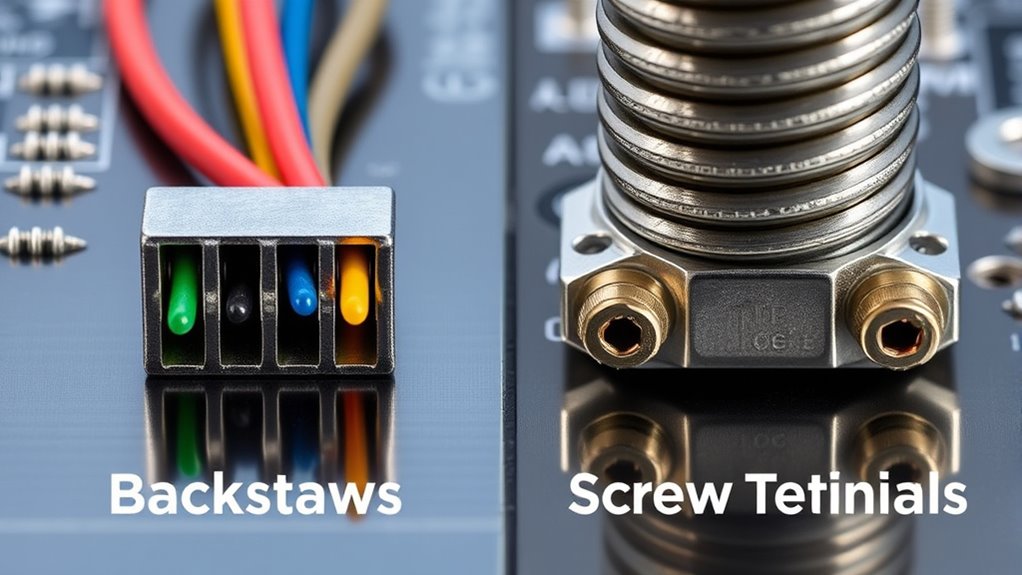

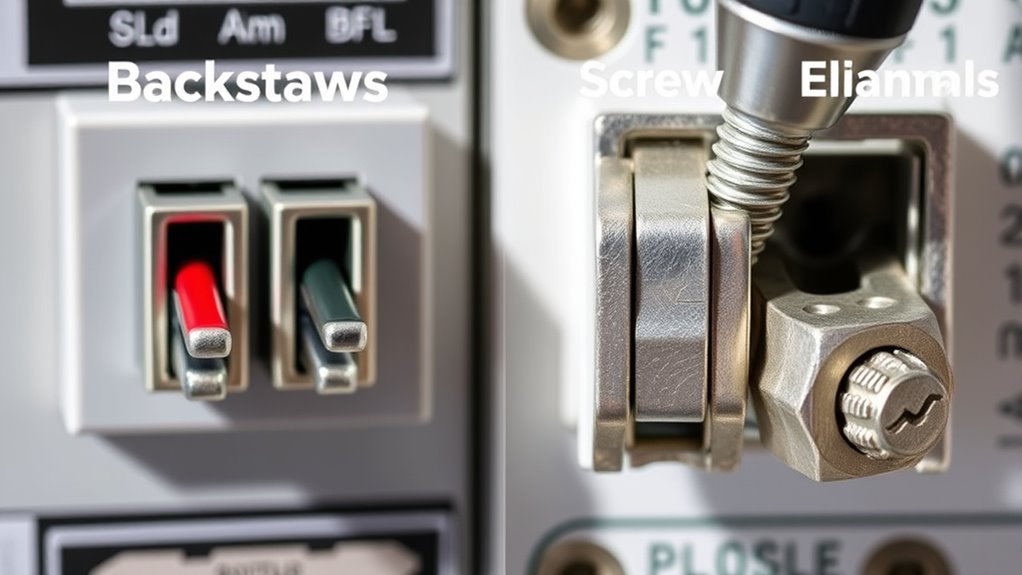

Understanding the Basic Design and Functionality

Backstabs and screw terminals are both common methods for connecting wires to electrical components, but they differ markedly in design and function. The key difference lies in their material composition and how they conduct electricity. Backstabs use a metal spring-loaded blade that pierces the wire insulation, ensuring a secure connection. These blades are typically made from brass or phosphor bronze, chosen for their excellent electrical conductivity. Screw terminals, on the other hand, involve wrapping the wire around a screw that tightly clamps it in place. The screw and terminal block are usually made from copper or brass, both offering high electrical conductivity. This design provides a reliable connection, but the materials’ quality directly impacts conductivity and overall performance. Understanding these differences helps you choose the right connection type based on material and conductivity. Additionally, the material quality of the components plays a crucial role in ensuring long-term durability and safety of the connections. It is also important to consider installation practices to prevent potential problems such as loose connections or corrosion. Proper connection techniques can significantly affect the reliability of the connection, and incorporating quality standards ensures compliance with safety regulations. Furthermore, selecting high-quality connectors and adhering to recommended installation standards can greatly enhance overall electrical safety and performance.

Ease of Installation and Use

When it comes to installation and everyday use, backstabs offer a quick and straightforward method. You can easily insert wires without needing tools like screwdrivers, making the process faster, especially for DIY projects. This simplicity is ideal if you’re exploring wireless alternatives and want a clean, clutter-free setup. Backstabs also contribute to an aesthetic design by minimizing visible connections and reducing bulky components. Additionally, they are designed to be compatible with modern electrical components, emphasizing their suitability for current best modern toilet designs that favor streamlined features. Properly designed connection methods can significantly impact the overall safety and reliability of your wiring. As with many electrical connection techniques, the choice can influence the durability and performance of your setup. Using standardized wiring practices ensures compatibility and reduces the risk of faults over time. However, screw terminals might take slightly longer to install but offer a more secure connection. For users prioritizing ease of use and a sleek look, backstabs are advantageous. They streamline installation, save time, and enhance the visual appeal of your setup. Moreover, installation techniques can impact the reliability and safety of your wiring, making the choice of connection method important. Ultimately, backstabs make everyday wiring more accessible, especially if convenience and aesthetics matter most to you.

Reliability and Connection Security

Mechanical stability is vital for maintaining a secure connection over time. You’ll want to take into account how well each terminal resists vibration and movement. Stronger, more stable connections prevent failures and guarantee reliable performance. Additionally, understanding industry transformations can help you select terminals that are future-proof and adaptable to evolving technologies. For example, signs of spoilage in materials or connections can indicate potential issues and guide your choice of more durable options. Incorporating material durability considerations ensures longevity and consistent performance in various environments. Monitoring storage conditions can also help prevent premature failure and maintain connection integrity. Exploring protective styling benefits from related textile techniques might inspire innovative approaches to enhance connection resilience.

Mechanical Stability Matters

Ensuring a secure connection is crucial for the long-term reliability of your electrical setup. Mechanical stability directly impacts how well your connections stay intact over time, especially under strain or minor movements. Screw terminals typically offer better stability because they physically clamp the wire tightly, reducing the risk of loosening. Backstabs, while quicker to install, may lack this robustness, risking connection failure. Aesthetic differences matter too—screw terminals often come with color options that help you identify circuits easily, adding to the overall neatness. Choosing the right terminal type isn’t just about convenience; it’s about ensuring your connection remains secure and durable. Mechanical stability isn’t just a detail—it’s a fundamental factor that influences the long-term performance of your electrical system. Understanding connection quality can help you make more informed choices about terminal types, especially considering connection security. Additionally, selecting terminals with robust clamping mechanisms can further enhance connection stability and reduce maintenance needs over time.

Resistance to Vibration

Vibration can pose a significant threat to the stability of electrical connections, especially in environments subject to motion or mechanical shocks. If your setup experiences constant movement, choosing a connection method with high resistance to vibration is essential. Screw terminals offer superior reliability by maintaining tight, secure connections under dynamic conditions, reducing the likelihood of disconnections or failures. This enhances the overall environmental impact by preventing potential malfunctions that could lead to waste or damage. Additionally, screw terminals often provide a cleaner, more organized appearance, maintaining aesthetic appeal even in vibrating environments. In contrast, backstabs may loosen over time, risking connection loss. To guarantee long-term connection security, prioritize methods proven to withstand vibration, increasing overall connection stability, safeguarding both your equipment’s performance and visual integrity. Proper connection methods are crucial for ensuring reliable electrical performance in vibrating environments.

Durability and Long-Term Performance

When considering durability and long-term performance, you need to think about how well the connection withstands corrosion over time. Mechanical stability under load ensures your setup stays secure, even after years of use. Additionally, resistance to wear and tear determines whether the connection remains reliable in demanding conditions. Implementing secure connection methods can further enhance overall system resilience and reduce the risk of failures. Regularly inspecting connection points and choosing appropriate materials can also significantly improve longevity and reliability. Incorporating security system components designed for durability can provide added assurance against environmental factors. Furthermore, understanding the Italian cuisine influences that shape food preparation and presentation, much like understanding environmental factors that impact equipment longevity, is essential for optimal performance.

Corrosion Resistance Over Time

Over time, corrosion resistance markedly impacts the durability of backstabs and screw terminals. If you opt poorly, galvanic corrosion can weaken connections, especially in humid or salty environments. Proper environmental sealing helps prevent moisture ingress, extending lifespan. Here are key points to contemplate:

- Backstabs may be more vulnerable to galvanic corrosion without adequate sealing.

- Screw terminals often feature better environmental sealing, reducing corrosion risk.

- Long-term exposure to moisture accelerates corrosion, impacting conductivity.

- Regular maintenance and protective coatings can boost corrosion resistance for both types.

Understanding how environmental sealing and galvanic corrosion affect your connections ensures you select the right terminal for durability over time. Proper choices protect your system’s reliability and prevent costly failures.

Mechanical Stability Under Load

Mechanical stability under load is essential for ensuring long-term performance of terminal connections. When subjected to thermal expansion, materials in the connection can shift or loosen if not properly designed, risking failure over time. Screw terminals typically provide a secure hold, maintaining consistent pressure even under temperature fluctuations, which enhances durability. Backstabs, however, may loosen due to thermal movement, compromising stability. Good electrical conductivity is also crucial; stable contacts prevent increased resistance and overheating. Ensuring the connection withstands mechanical stress without degrading requires choosing terminals that resist loosening and maintain conductivity under load. Proper design and material selection help achieve this stability, ensuring your connections remain reliable for long-term operation without the risk of failure caused by thermal expansion or mechanical fatigue.

Wear and Tear Resistance

Durability and long-term performance are essential when choosing between backstabs and screw terminals, as repeated connections and disconnections can cause wear. To guarantee longevity, consider how material compatibility and environmental protection affect wear resistance.

- Material Quality: High-quality metals resist corrosion and reduce wear over time.

- Environmental Factors: Exposure to moisture, dust, or chemicals accelerates deterioration.

- Connection Method: Screw terminals often withstand repeated use better than backstabs, which may loosen or degrade.

- Design Features: Components with reinforced contact points and protective coatings enhance durability.

Safety Considerations and Potential Hazards

While both backstabs and screw terminals are commonly used for electrical connections, they each pose specific safety risks if not handled properly. Improper installation can lead to electrical shock or fire hazards. Loose connections may produce heat buildup, increasing fire risk, while poor contact can cause arcing. To stay safe, ensure connections are tight and secure. Use appropriate tools and follow safety procedures.

| Risk | Prevention |

|---|---|

| Electrical shock | Turn off power before working on connections |

| Fire hazards | Regularly inspect and tighten terminals |

| Loose connections | Use suitable terminals for the wire size |

| Overheating | Avoid overloading circuits |

| Arcing | Maintain clean, corrosion-free contacts |

Cost and Suitability for Different Projects

Choosing the right connection method depends not only on safety but also on cost and how well it suits your project needs. When considering cost comparison, backstabs are generally more affordable upfront but may incur higher long-term costs due to maintenance or replacements. Screw terminals tend to have a higher initial price but offer better durability and lower ongoing expenses. To determine project suitability:

- For quick, low-cost setups, backstabs are suitable.

- For projects requiring frequent adjustments, screw terminals provide flexibility.

- High-vibration environments benefit from screw terminals’ secure connections.

- Large-scale or professional applications often favor screw terminals for reliability.

Your choice hinges on balancing budget constraints with the demands of the project, ensuring you select the most cost-effective and suitable connection method.

Frequently Asked Questions

Can Backstabs Be Reused After Removal?

Backstabs generally can’t be reused after removal because the removal process often damages the metal contact or spring mechanism. Reusing them risks poor electrical connection or failure. If you’re considering reuse potential, it’s best to examine the backstab for any signs of wear or deformation. Usually, replacing them ensures a secure, reliable connection, preventing potential electrical issues down the line.

Are Screw Terminals Suitable for High-Current Applications?

Ever wondered if screw terminals can handle high-current applications? They’re generally suitable if you choose ones with a high current capacity, often rated for significant loads. Plus, screw terminals tend to offer a more secure connection, reducing the risk of loosening under heavy current. While installation might be a bit more complex, their durability and reliable contact make them ideal for high-current environments. Are you ready to upgrade your connections?

How Do Environmental Factors Affect Terminal Performance?

Environmental factors critically impact terminal performance. You need to account for corrosion resistance, especially in humid or salty environments, as it prevents oxidation that can weaken connections. Temperature stability is also vital; extreme heat or cold can cause materials to expand, contract, or degrade, leading to loose connections or failure. By choosing terminals with high corrosion resistance and good temperature stability, you guarantee reliable, long-lasting performance even under harsh environmental conditions.

What Maintenance Is Required for Both Connection Types?

Maintaining your terminal connections matters for maximizing connection durability and minimizing installation complexity. Regularly inspect for corrosion, looseness, or wear, and clean or tighten connections as needed. For backstabs, ensure the spring mechanism functions smoothly, while screw terminals benefit from periodic tightening. Proper, proactive maintenance prevents problems, preserves performance, and prolongs lifespan, making your connections reliable and resilient against environmental challenges.

Which Connection Type Is Better for Automation Systems?

You should choose screw terminals for automation systems because they handle a wider range of wire gauge compatibility and offer more secure, reliable connections. They may involve slightly higher installation complexity, but their durability makes them ideal for critical applications. Backstabs, while easier to install, often lack the robustness needed for automation. So, for long-term stability and flexibility, screw terminals are your best bet.

Conclusion

Ultimately, choosing between backstabs and screw terminals depends on your project‘s priorities. Backstabs boast quick, convenient connections, while screw terminals promise superior security and strength. Consider your needs carefully—prioritize safety, stability, and sustainability for lasting success. By weighing the wins and woes of each option, you’ll walk away with a wise, well-informed choice that works wonders for your wiring wonders. Make your decision wisely, and your project will prosper perfectly.