To pick the right wire gauge every time, you need to understand its standardized system that measures wire thickness with numbers and color codes. Thicker wires carry more current, while thinner ones are suited for low-power tasks. Always consider your project’s current load, length, and environment. Using the correct gauge prevents hazards like overheating or voltage drops. Keep these tips in mind, and you’ll be on your way to choosing the perfect wire every time.

Key Takeaways

- Understand that smaller gauge numbers indicate thicker wires, which support higher current capacities.

- Use wire gauge charts and measurements (in inches or millimeters) to select the correct size for your application.

- Match the wire gauge and insulation type to ensure safety, flexibility, and durability.

- Consider current load, length, and voltage drop to prevent overheating and efficiency loss.

- Always consult standards and perform calculations to avoid common sizing mistakes and ensure proper wire selection.

Understanding the Wire Gauge System

The wire gauge system provides a standardized way to measure the thickness of electrical wires, which is crucial for ensuring safety and proper performance. You’ll notice color codes that help identify wire sizes quickly, simplifying selection and installation. Different insulation types, like PVC or rubber, can affect wire flexibility and durability, but they don’t change the gauge measurement itself. Understanding these color codes is essential for matching the right gauge to your project’s needs, preventing overheating or electrical failures. When you choose a wire, pay attention to both the gauge number and insulation type, as they work together to ensure safety and efficiency. Mastering this system helps you make informed decisions, ensuring your electrical work is both reliable and compliant with safety standards.

Why Wire Size Matters for Your Projects

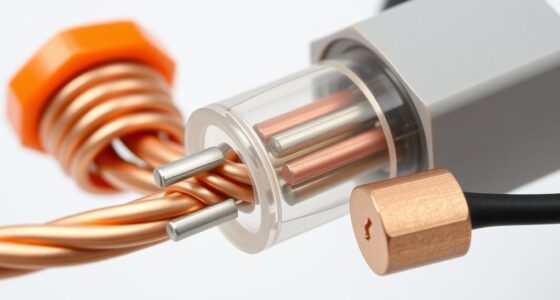

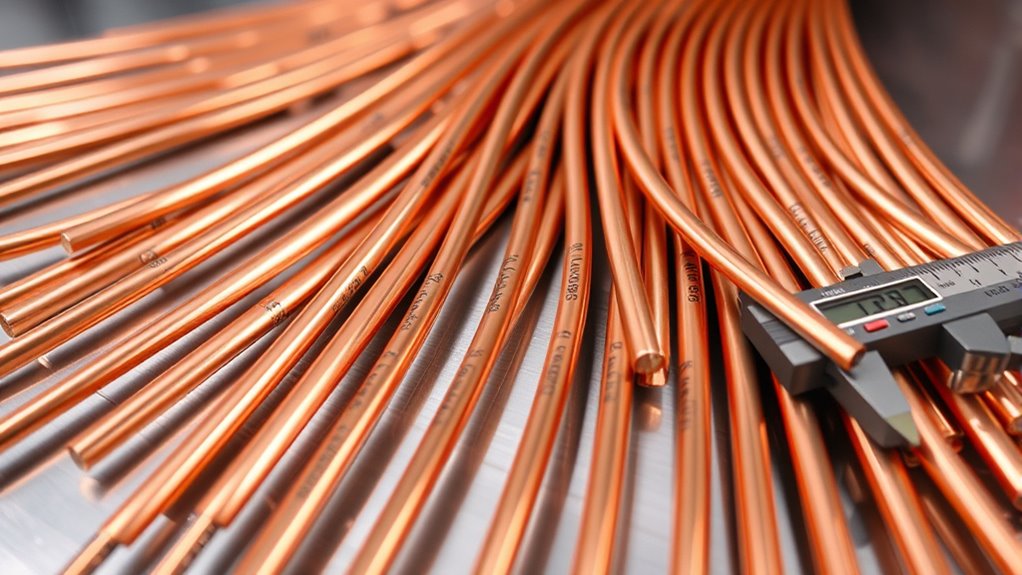

Choosing the right wire size is essential because it directly impacts the safety and efficiency of your electrical projects. Using an incorrect size can lead to overheating, voltage drops, or even fires. The wire material, whether copper or aluminum, influences current-carrying capacity, so selecting the proper gauge guarantees reliable performance. Additionally, insulation types matter; some insulations handle higher temperatures or provide better protection against environmental factors. When your wire is appropriately sized, it reduces the risk of damage and improves overall system longevity. Proper wire gauge selection ensures your project adheres to electrical standards and operates safely. Understanding the importance of correct wire sizing helps prevent potential hazards and ensures compliance with safety regulations. Properly sizing wires also accounts for voltage drop, which can affect device performance over longer distances. Whether you’re wiring a small appliance or a major circuit, understanding why wire size matters helps you make informed choices, ensuring your project is safe, efficient, and compliant with electrical standards. Recognizing the importance of electrical safety can prevent costly mistakes and hazards. Considering vehicle wiring standards and practices can also aid in understanding how proper wire sizing applies across various applications.

How to Read a Wire Gauge Chart

To read a wire gauge chart, you need to understand the gauge numbering system and what the numbers represent. You’ll also compare the diameters and cross-sectional areas to choose the right wire. Additionally, knowing how metric and imperial units relate helps you interpret the chart accurately. Recognizing wire gauge standards ensures you select the appropriate size for your specific application. Familiarity with standardized measurements allows for more precise and consistent wire selection across different projects. Understanding the side effects of improper gauge selection can help prevent electrical hazards and ensure safety. Moreover, being aware of the application-specific requirements helps in choosing the most suitable wire gauge for various tasks. Incorporating space optimization techniques in your workspace can make handling and organizing wires easier, reducing clutter and improving efficiency.

Understanding Gauge Numbering System

Ever wonder how to quickly interpret a wire gauge chart? It’s simpler than you think. The gauge number indicates the wire’s diameter, with smaller numbers representing thicker wires. This system applies across different wire materials, like copper or aluminum, so always check the specific chart. Insulation types also matter because they can affect the overall size and compatibility, but the gauge number itself refers to the bare conductor’s diameter. Most charts are arranged inversely, with gauge numbers decreasing as wire thickness increases. Understanding this numbering system helps you select the right wire for your project, ensuring safety and performance. Remember, the gauge number is a universal language in wiring, making it easier to compare and choose the proper wire regardless of material or insulation.

Interpreting Diameter and Area

Have you ever looked at a wire gauge chart and wondered how to interpret the diameter and cross-sectional area? Your wire gauge number actually relates directly to its wire diameter—the thicker the wire, the higher the gauge number, and vice versa. The chart provides a clear way to see this relationship, showing the wire diameter in inches or millimeters. The cross-sectional area, usually measured in square mils or square millimeters, indicates how much space the wire’s core occupies. Larger cross-sectional areas mean more current-carrying capacity. By understanding how to read these measurements, you can accurately determine the wire’s size and suitability for your project. This knowledge helps you select the right gauge, ensuring safety, efficiency, and performance in your electrical work.

Comparing Metric and Imperial Units

Understanding how to read a wire gauge chart requires knowing how metric and imperial units are used to represent wire sizes. Imperial units, like AWG, measure wire diameter, with smaller numbers indicating thicker wires. Metric units, such as millimeters, specify diameter directly. When comparing these systems, pay attention to wire color codes, which often indicate gauge size, and insulation types, which can affect overall diameter. For example, a thicker wire with a specific wire color might be equivalent to a different gauge in the metric system. Recognizing these differences helps you select the right wire, ensuring compatibility with your project and safety standards. Additionally, understanding the measurement systems used in wire sizing can help you make safer and more efficient choices. Being familiar with standardized wire markings allows for quick identification and reduces the risk of errors. Properly interpreting these standards can also influence the lifestyle implications of your wiring decisions, promoting safety and reliability. By understanding both measurement systems, you can confidently interpret wire gauge charts and pick the correct size every time.

Common Wire Gauges and Their Uses

Different wire gauges are designed for specific applications, balancing flexibility, current capacity, and durability. For example, thinner gauges like 22 or 24 are flexible and often used for wire color coding in electronics, with insulation types such as PVC or silicone. Thicker gauges like 10 or 12 handle higher currents, suitable for heavy-duty tasks like appliances or automotive wiring. Here’s a quick look:

| Gauge | Typical Use |

|---|---|

| 22-24 | Signal wiring, electronics |

| 14-16 | Lighting, small appliances |

| 10-12 | Power tools, automotive wiring |

| 8-10 | Industrial equipment |

| 2-4 | Heavy-duty applications |

Knowing these common gauges helps you select the right wire for your needs, considering wire color coding and insulation types for safety and efficiency. Additionally, understanding wire gauge standards ensures proper application and safety compliance. It is also important to consider the current capacity of each gauge to prevent overheating or electrical failures.

Factors to Consider When Choosing Wire Gauge

When selecting a wire gauge, you need to consider the current load capacity to guarantee the wire can handle the power without overheating. The length of the wire and voltage drop also play a vital role in maintaining efficiency and safety. By paying attention to these factors, you can choose a gauge that meets your specific electrical needs effectively. Additionally, understanding the wire jack types can ensure compatibility with your devices and prevent connection issues. Recognizing the wire gauge standards can further help you select the appropriate size for various applications. It’s also important to consider insulation types to ensure proper protection and durability in different environments. Being aware of GMC tuning techniques can help optimize your vehicle’s electrical system and overall performance for specific modifications.

Current Load Capacity

How much current your wire needs to carry is a critical factor in choosing the right gauge. If the wire isn’t thick enough, it can overheat, causing safety hazards and failures. To guarantee proper power capacity and safety considerations, select a gauge that handles your expected load comfortably.

| Current Load | Recommended Wire Gauge |

|---|---|

| Up to 15A | 14 AWG |

| 20A – 30A | 12 AWG |

| 40A – 50A | 10 AWG |

| Over 50A | 8 AWG or thicker |

Choosing the correct gauge ensures your system operates efficiently and safely, preventing potential hazards caused by overloads.

Length and Voltage Drop

Length and voltage drop are critical factors when choosing the right wire gauge because excessive voltage loss can impair device performance and cause system inefficiencies. Longer wire runs increase resistance, leading to voltage drops that may weaken signals or reduce power. To minimize this, select a thicker gauge wire suited for your distance. Consider insulation types, as some insulation materials impact heat dissipation, affecting voltage stability over length. Proper installation techniques also matter—secure connections and appropriate routing reduce unnecessary resistance. If your wire run is extensive, upgrading to a larger gauge can prevent voltage drops that compromise safety and efficiency. Always evaluate the total length and load to determine the most suitable gauge, ensuring your system runs smoothly without unnecessary power loss. Additionally, understanding wire gauge standards can help you make informed decisions for your specific application. Being aware of ampacity ratings ensures you select a wire size that safely handles the current load without overheating. Recognizing voltage drop limits in your system design can further help maintain optimal performance and safety. Considering system load requirements can also influence your choice, especially in high-demand setups. When planning your wiring, it’s also helpful to consult industry guidelines to ensure compliance with safety standards and best practices.

Tips for Safely Working With Different Wire Sizes

Working safely with different wire sizes requires understanding their specific properties and handling requirements. Always prioritize wire safety by wearing protective gear and avoiding damaged or frayed wires. The insulation significance cannot be overstated; ensure wires are properly insulated to prevent shorts and electric shocks. When working with thinner wires, handle them gently to avoid breaking the insulation or causing accidental contact. For thicker gauge wires, use the correct tools to prevent damage and ensure secure connections. Keep your workspace organized, and double-check your connections before powering up. Remember, proper insulation and careful handling are key to avoiding accidents. Paying attention to wire gauge and insulation quality ensures safer and more reliable electrical work. Additionally, understanding the maintenance of wires and connectors can extend their lifespan and improve safety. By respecting wire safety protocols and understanding insulation importance, you can work efficiently and safely, reducing risks associated with different wire sizes.

Mistakes to Avoid When Selecting Wire Gauge

Choosing the correct wire gauge is essential for safety and performance, but mistakes here can lead to serious problems. Wire gauge confusion often causes sizing errors that compromise safety and cause equipment failure. One common mistake is selecting a wire that’s too thin for the current load, risking overheating and fires. Conversely, using a wire that’s thicker than necessary can be costly and unwieldy. Another error is ignoring voltage drop over long distances, which can reduce efficiency. Always double-check the ampacity and distance to ensure proper sizing. Avoid relying solely on guesswork or vague guidelines—use precise charts and calculations. Sizing errors can be easily prevented with careful research and attention to detail, saving you from costly repairs and safety hazards down the line.

Frequently Asked Questions

How Do Temperature Changes Affect Wire Gauge Selection?

Temperature changes impact wire gauge selection because thermal expansion can cause the wire to expand, affecting current flow. When temperatures rise, the material’s conductivity may decrease, increasing resistance and potential overheating. You should choose a thicker gauge for high-temperature environments to guarantee safety and efficiency. Conversely, at lower temperatures, a slightly thinner wire might suffice. Always consider temperature effects to maintain ideal performance and prevent electrical issues.

Can Using a Thicker Wire Improve Electrical Efficiency?

Using a thicker wire can improve electrical efficiency because it reduces resistance, which helps minimize voltage drop over long distances. Choosing the right conductor materials, like copper or aluminum, also plays a key role in efficiency. Thicker wires carry more current with less heat and power loss, ensuring your electrical system runs smoothly. So, upgrading to a larger gauge can be beneficial, especially for high-demand or long-distance applications.

What Are the Signs of Using an Incorrect Wire Gauge?

When using an incorrect wire gauge, you might notice circuit overloads, causing breakers to trip frequently. Insulation melting or discoloration is a clear sign that the wire is too thin for the current load. You may also experience flickering lights or a burning smell. These issues indicate that your wiring isn’t suitable for your needs, risking damage and safety hazards. Always check the gauge to guarantee safe and efficient electrical performance.

How Does Wire Insulation Impact Gauge Choice?

Insulation influences insulation impacts your ideal wire gauge choice. Thicker insulation material provides better protection but adds bulk, reducing flexibility considerations and possibly requiring a larger gauge for safe current flow. Conversely, flexible insulation materials allow for easier maneuverability, often fitting smaller gauges. Always match insulation type with your project’s needs, balancing protection and flexibility, so your wiring remains safe, efficient, and adaptable.

Are There Industry Standards for Specific Wire Gauges?

Yes, industry standards for specific wire gauges exist, rooted in wire gauge history and wire gauge conversion. These standards, set by organizations like the American Wire Gauge (AWG), guarantee safety and compatibility across electrical systems. When selecting wire, you should always check these standards to match the gauge with your project’s requirements, considering factors like current load and insulation type, to ensure your wiring is both safe and effective.

Conclusion

Picking the right wire gauge is like choosing the perfect brush for a masterpiece—your project depends on it. By understanding the system, reading charts, and considering your needs, you’ll avoid costly mistakes and guarantee safety. Think of it as charting a course; with the right gauge, you’ll reach your destination smoothly. Trust your judgment, stay informed, and your DIY journey will be as seamless as a painter’s confident stroke.